SCR Catalyst Retrofitting

Modular Complete MWM Solution

- Reliable reduction of plant emission values

- Urea solution MWM Premium U 32.5

SCR Catalyst Retrofitting

Modular Complete MWM Solution

- Reliable reduction of plant emission values with SCR (selective catalytic reduction)

- Plant-specific modular turn-key solution

- Full scope retrofitting with urea tank and supply with MWM Premium U 32.5 urea solution possible

- Precise urea injection technology, controlled by the actual NOx values measured

- Quality assurance by the manufacturer

- State-of-the-art technology

- Service and maintenance by MWM personnel

- Remote system access ensures quick support and high system availability

On this page

Video: SCR Catalyst (in German)

SCR catalyst components

Products and services

Benefits of SCR catalyst retrofitting

Flyer SCR Catalyst Retrofitting (in German)

Product Flyer MWM Premium U 32.5 (in German)

Comply with Emission Limits While Ensuring Plant Efficiency and Availability

Selective Catalytic Reduction (SCR) is an advanced active emissions control technology system that reduces emissions of nitrogen oxides NOX in a sustainable and long-term manner. It has a direct impact on purity of exhaust gases released into the atmosphere, and accordingly contributes to environmental protection.

Video: SCR Catalyst (in German)

ЗАЯВЛЕНИЕ О КОНФИДЕНЦИАЛЬНОСТИ: при воспроизведении данного видео действует политика конфиденциальности YouTube. /// PRIVACY NOTE: If you play a video, privacy regulations of YouTube apply.

All languages of the video on YouTube: DE

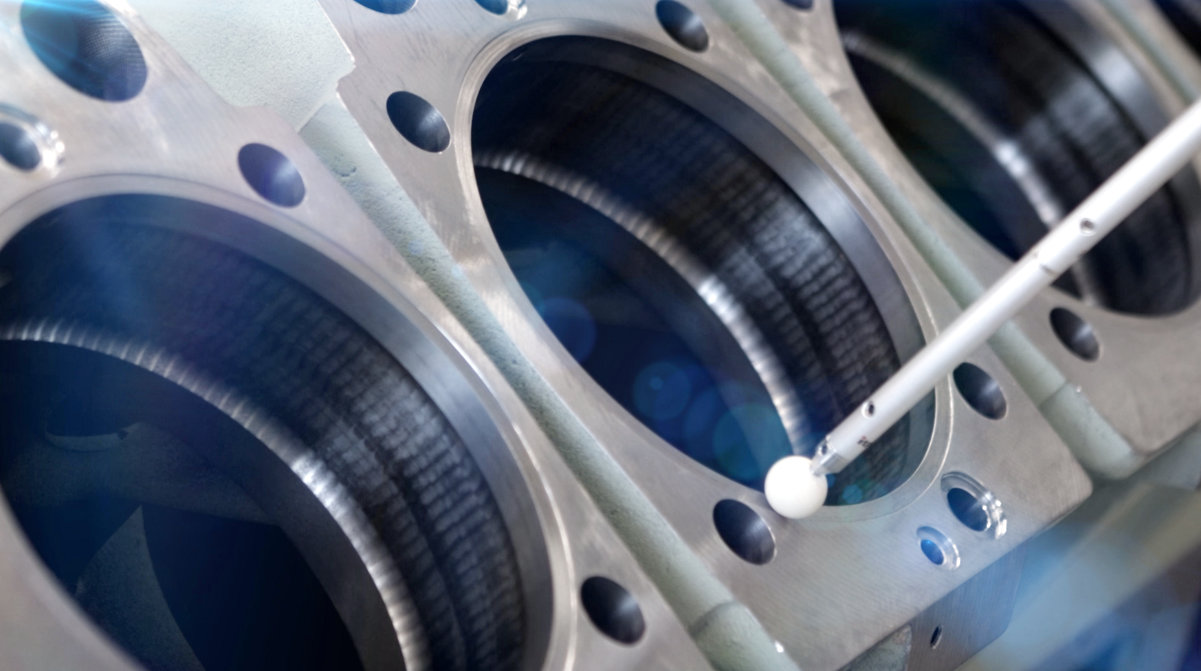

The SCR catalyst components

(can be implemented in the form of a containerized solution or in a building):

- SCR catalyst housing

- SCR catalyst and oxidation catalyst honeycomb

- Dosing unit

- Control

- Injection section

- Compressed air unit

- Urea tank

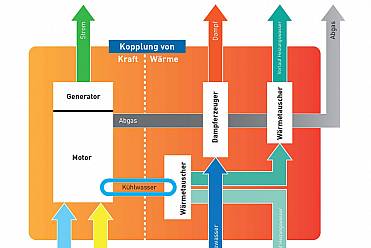

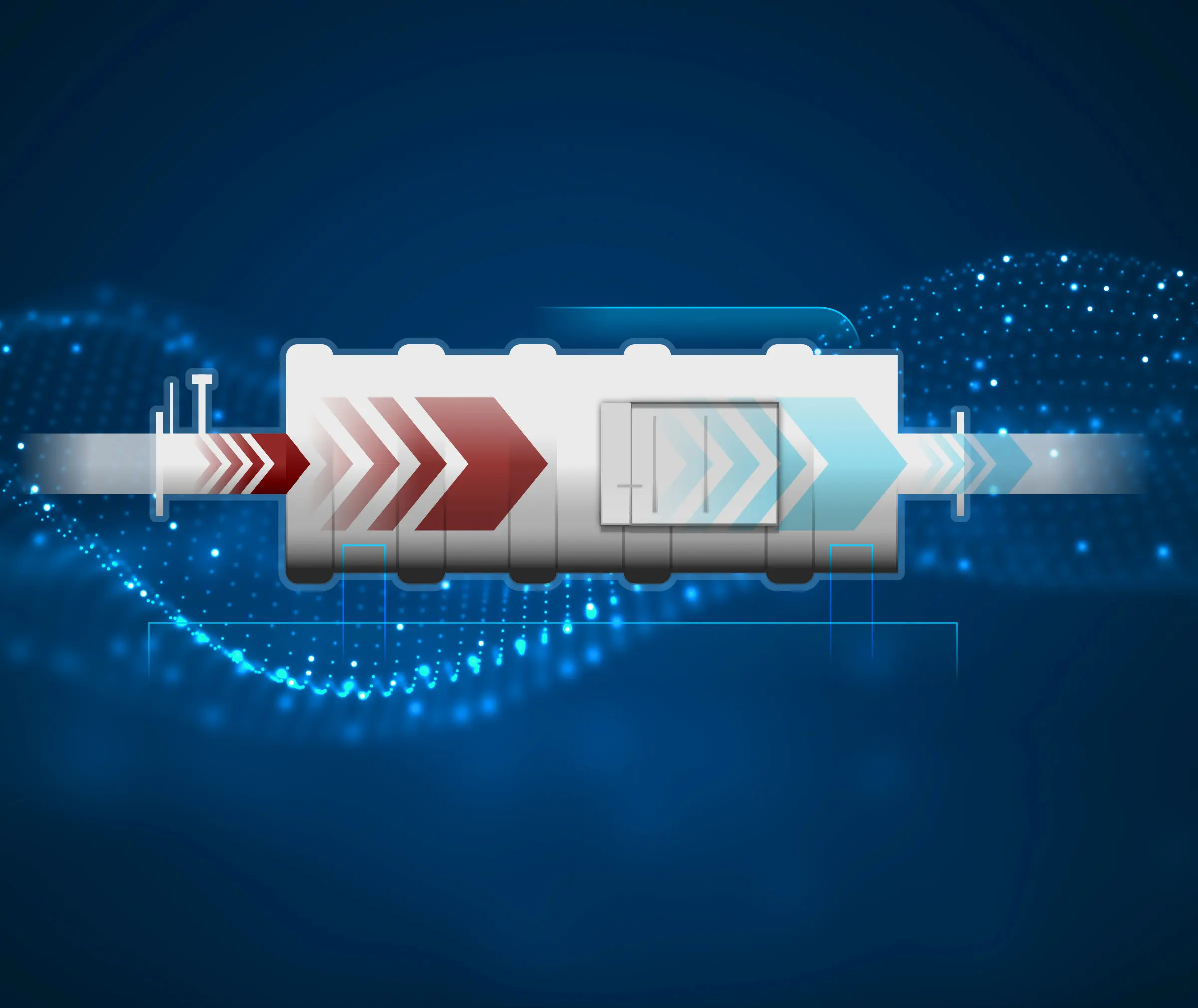

A urea-water solution is injected into the exhaust gas after the gas engine and before the catalyst. The thermolysis and hydrolysis in the exhaust gas produces ammonia (NH3) and carbon dioxide (CO2). In the catalyst, the ammonia causes a reduction of NOX, resulting in nitrogen and water.

Apart from the catalyst, we can offer you the following products and services:

- Urea tank

- Urea solution MWM Premium U 32.5

- Service and maintenance

- Financing from 0% p.a.

Easy retrofitting by MWM Service:

For the retrofitting of existing plants, MWM offers a compact turn-key solution with SCR catalyst, optionally also with urea tank and urea solution. As the retrofitting of existing plants takes very little time, the downtime is very short. Moreover, MWM Service evaluates all the steps that need to be taken in advance in order to ensure a smooth and speedy transition. After the existing peripherals have been disconnected, the new SCR catalyst can be mounted. Additionally, the urea tank is set up, the control system is installed, and the SCR system is linked to and integrated in the existing engine control. Optional remote system access ensures quick support and high system availability.

Benefits of MWM SCR catalyst retrofitting at a glance:

- Modular complete solution in compact design

- Even more efficient plant operation with reduced emissions

- Service and maintenance by qualified personnel

- Comprehensive EPC (engineering, procurement, and construction) retrofit solution including urea tank and urea solution

- State-of-the-art urea injection technology, controlled by the actual NOX values measured

- Remote access to the system for quick support and high system availability

Flyer SCR Catalyst Retrofitting (in German)

Download PDF: DE

Product Flyer MWM Premium U 32.5 (in German)

Download PDF: DE

Order your SCR catalyst retrofit set in the service shop or contact your service partner.

For general inquiries concerning service products, contact: serviceproducts@mwm.net

Gas Engines & Products

Cogeneration Power Plant Solutions

Eco-friendly MWM cogeneration power plants with combined heat and power enable decentralized, economical and energy-efficient power production.

Container Cogeneration Plant

Compact modules for the TCG 3016, TCG 3020 and TCG 2020 gas engines. Complete turnkey systems for special applications.

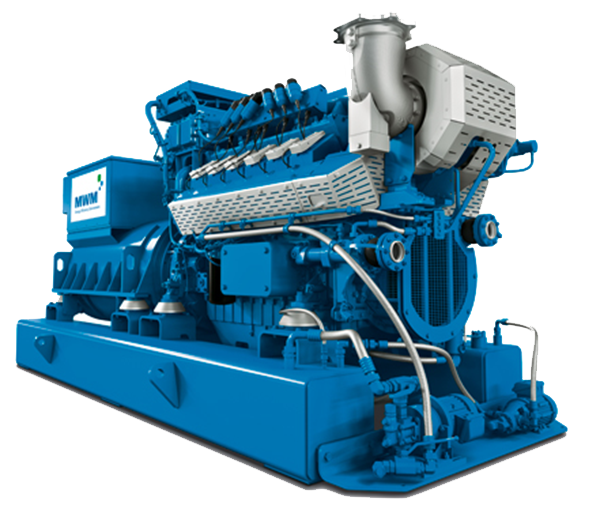

Gas Engine TCG 3016

New development – greatly reduced operating and installation costs and fully digitized power plant control.

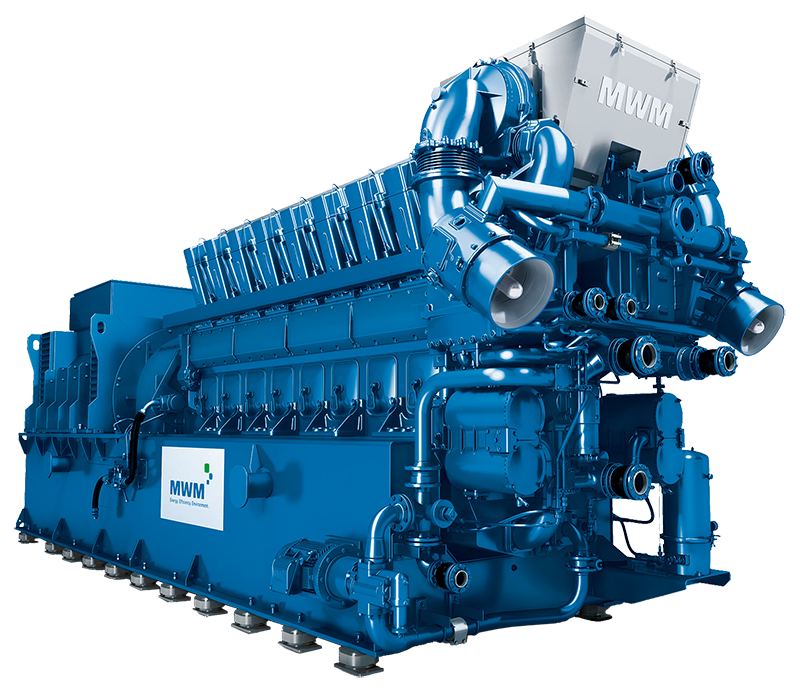

TCG 2032

High reliability. Low operating costs. Gas types: natural gas, landfill gas, sewage gas, mine gas, coke oven gas. Mainly used in large IPP projects with up to 100 MWel.

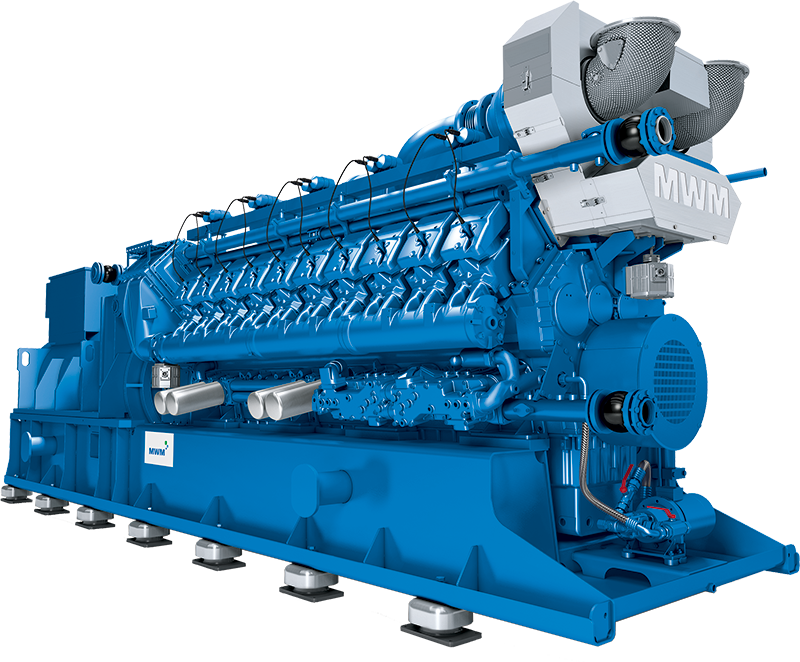

Gas Engine TCG 2020

Best electrical and thermal efficiency in its class. All gas types: natural gas, biogas, mine gas, landfill gas, sewage gas.

Contact Sales & Service

MWM Austria GmbH Archengasse 24C A-6130 Schwaz Austria

T +43 5242 21300 E info-eeca@mwmenergy.com W www.mwm.at