MWM Remote Asset Monitoring (RAM) Now Also Available for Gas Engines with TPEM Power Plant Control

Mannheim, September 26, 2022

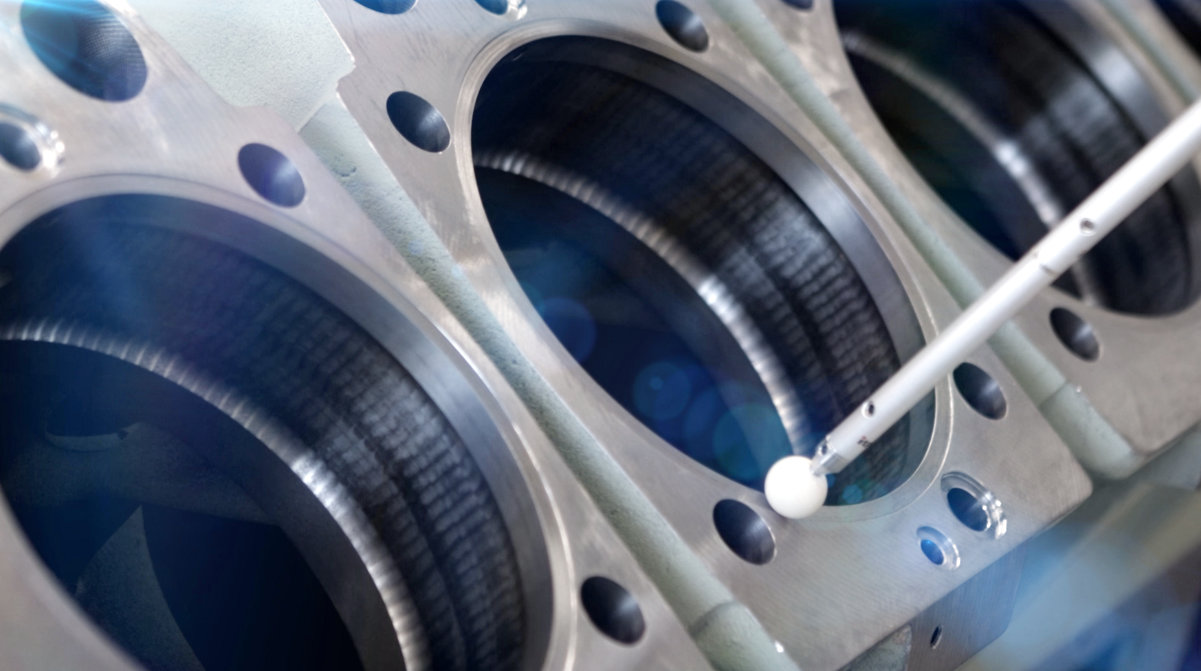

With immediate effect, the new online status monitoring system MWM Remote Asset Monitoring (RAM) is also available for MWM gas engines with the digital power plant control TPEM (Total Plant & Energy Management). MWM gas engines with TPEM control are now delivered RAM-ready. On request, existing plants can easily be upgraded with a retrofit kit.

Optimized Operation and Improved Maintenance of Gas Engines with the New MWM Online Status Monitoring System RAM, Now Also Available for TPEM

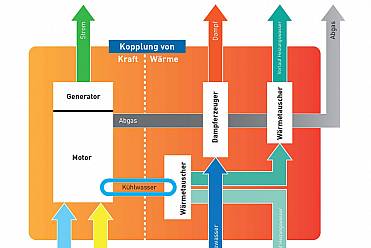

The combination of MWM RAM and the digital power plant control TPEM enables optimum operating support and optimization of the maintenance and servicing of gas engines, even remotely. To gain access to all benefits of RAM for gas engine gensets for combined heat and power generation in cogeneration power plants with TPEM control, all that needs to be done is to activate the RAM subscription online. For this, various subscription levels are available for selection under consideration of the needs for the operation and monitoring of the respective plant. No additional installation work, hardware, or complex wiring is required. Regular online updates make sure that the entire system is up to date and secure. Connectivity options include the existing TPEM Ethernet connection or, alternatively, a cellular connection. In this way, several gas engines or the entire fleet can easily be remotely supported and monitored.

RAM for TPEM Available Ex Works for New Gas Engines or as Retrofit Kit for Existing Plants

MWM gas engines are delivered RAM-ready, equipped with TPEM CC (Control Cabinet) Factory Fit. By default, the TPEM CC is equipped with the PLE telematics device required for RAM. As it is fully integrated in the TPEM control cabinet, no further wiring is required. By default, the TPEM Ethernet connection is used for the communication with the RAM servers; a cellular module is available on request. The easy online activation of RAM eliminates the need for work on site and additional traveling.

Even existing TPEM control cabinets can easily be upgraded with a retrofit kit. The retrofit kits are suitable for all existing TPEM control cabinets, and their functionality and appearance are equivalent to those of the ex-works integration. The retrofit kit also contains all required cabling and terminals.

Learn more about the benefits of RAM in combination with TPEM for the operation and servicing of gas engines and power plants.

For an overview of the various subscription levels, please refer to the flyer.

Flyer: MWM Remote Asset Monitoring – TPEM Integration

Click this brochure to access the digital publishing platform issuu.com. This website is governed by the issuu Privacy Policy.

All languages on issuu: EN | DE | ES | FR | NL | RU | CN

Download PDF: EN | DE | ES | FR | NL | RU | CN

Further information:

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com