MWM Gas Engines: Lower Operating Costs through Reduced Lubricant Consumption

Mannheim, June 8, 2016

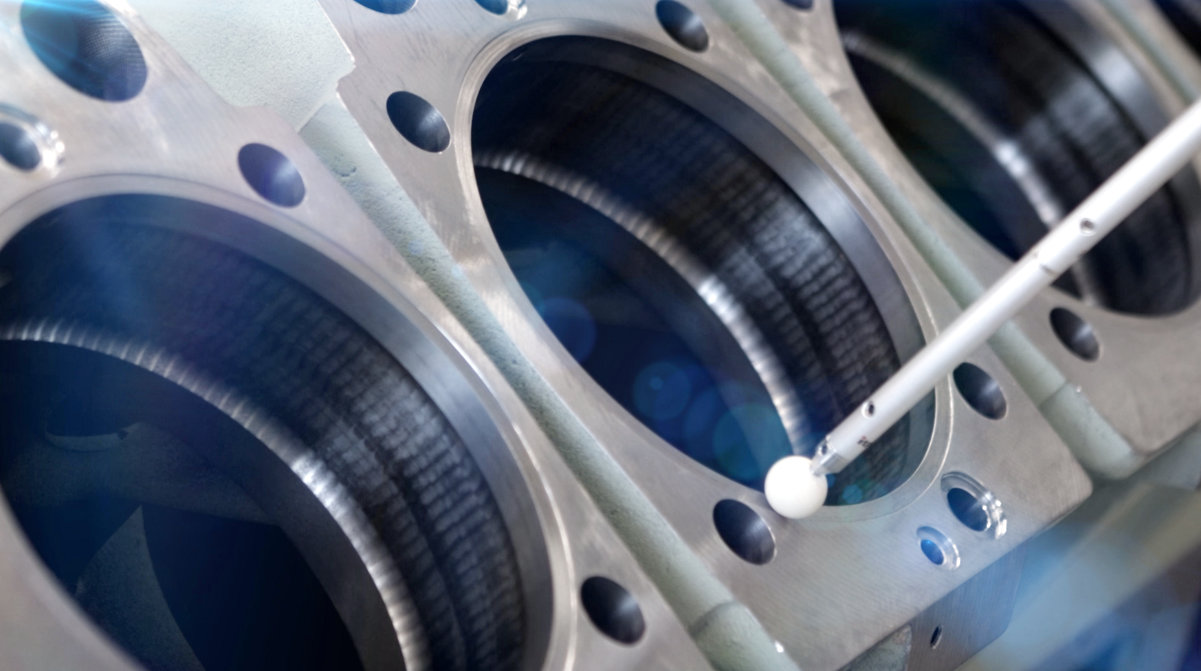

Apart from the fuel consumption and the maintenance costs of a gas engine, the average lubricant consumption is a key factor affecting the TCO (total cost of ownership) of a gas genset. Recent measurements, field tests, and further development of the model series show that MWM has succeeded in reducing the lubricant consumption of the gas engines.

Optimized Lubricant Consumption Values per Gas Engine in Detail

| Gas engine | Gas type | Service category | Lubricant consumption |

|---|---|---|---|

| TCG 2016 | Natural gas | 400 / 600 / 800 kWel | 0.20 g/kWh |

| TCG 2016 | Natural gas | 515 kWel | 0.10 g/kWh |

| TCG 2016 | Biogas | 400 / 600 / 800 kWel | 0.10 g/kWh |

| TCG 2020 | Natural gas | 1000 / 1200 / 1560 / 2000 kWel | 0.15 g/kWh |

| TCG 2020 | Biogas | 1200 / 1560 / 2000 kWel | 0.15 g/kWh |

| TCG 2032 | Natural gas | 3333 / 4300 / 3000 / 4000 kWel | 0.20 g/kWh |

| TCG 2032 | Biogas | 3770 / 3510 kWel | 0.20 g/kWh |

| TCG 2032B | Natural gas | 4500 / 4050 kWel | 0.20 g/kWh |

Previous values:

- TCG 2016: 0.2 g/kWh

- TCG 2020: 0.2 g/kWh

- TCG 2032: 0.3 g/kWh

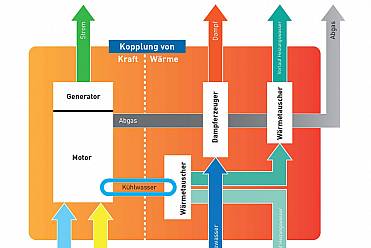

Reduced Operating Costs of CHP Plants

The main advantage for the customer is the reduction of the oil consumption and the associated financial savings. For example, the lubricant consumption of the MWM TCG 2032 gas engine series has been reduced by 0.1 g/kWh (from 0.3 g/kWh to 0.2 g/kWh). Based on an electrical output of 4,500 kWel the operator of an MWM combined heat and power (CHP) plant thus saves 450 g of lubricant an hour. Assuming 8,000 operating hours a year, the lubricant savings total 3,600 kg. Expressed in volume and hard currency, this means a significant reduction of operating costs.

Further information:

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com