MWM Distributor MKS Group of Companies Completes Innovative Power Plant Solution with MWM TCG 2032 Gas Engine for Enterprise NLMK Ural

Mannheim, February 20, 2020

In November 2019, MWM distributor MKS Group of Companies together with the MWM specialists successfully completed commissioning of the generating equipment at the power plant for NLMK Ural (NLMK Group), one of Russia’s largest enterprises, at its production site in Nizhniye Sergi, Sverdlovsk region. Design, equipment supply, construction, installation and commissioning of the power plant were completed by MKS Group of Companies within twelve months from laying the foundation to commissioning.

NLMK Ural is one of the major Russian manufacturers of blanks and rolled steel. NLMK Ural’s production cycle includes processes ranging from steelmaking to manufacturing finished long steel products. Every year NLMK Ural produces more than four million tons of long steel products. (Photo: provided by the press service of the MKS Group)

New Power Plant Enables Complete Covering of the Production Site’s Heat Consumption and 50 Percent of Electricity Consumption

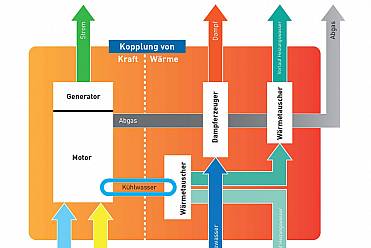

The power plant functions in cogeneration mode with simultaneous power and heat production. The energy complex houses an MWM TCG 2032B V16 unit and three gas fired hot-water boilers of 7 MW (megawatts) each. With 4.5 MW general electrical power and 25.5 MW thermal power the power plant became the most powerful gas engine power plant in the Nizhneserginsky district of the Sverdlovsk region. The total efficiency of the installation amounts to 86.5 percent. The power plant completely covers the demand of the production site’s heat consumption as well as 50 percent of the electricity consumption. The environmentally friendly power plant will also decrease the greenhouse emissions of the NLMK Ural enterprise by 4,000 tons per year.

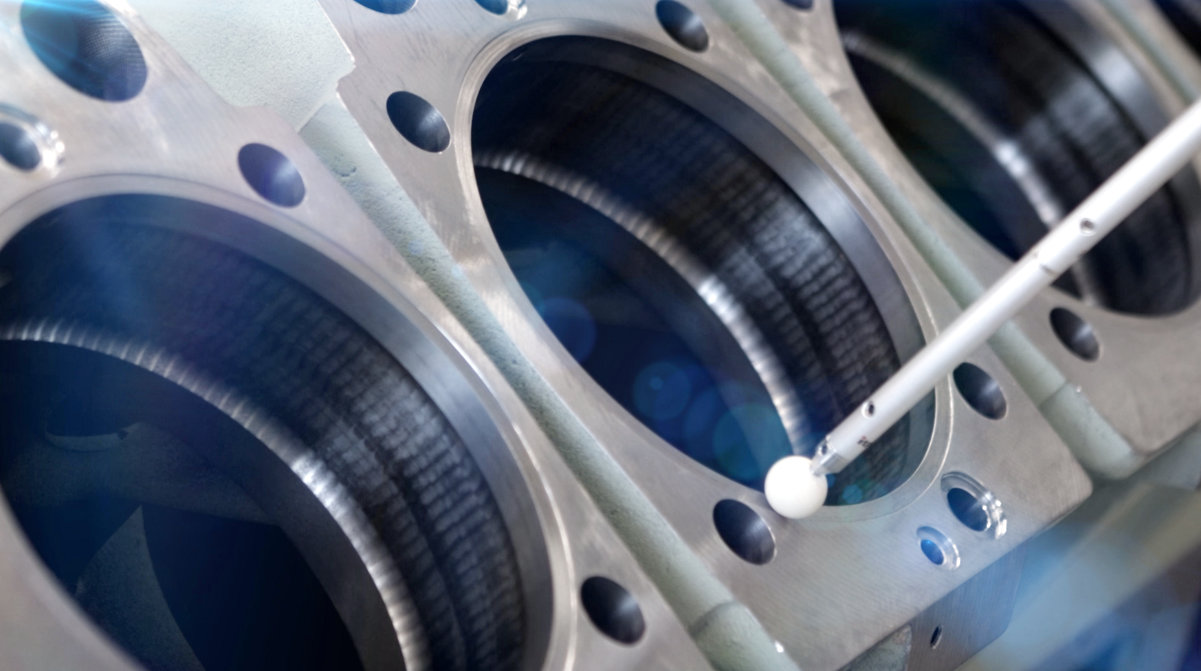

The installed MWM TCG 2032B V16 gas engine of the NLMK-Ural power plant in Nizhniye Sergi, Russia, produces an electrical output of 4.5 MW and, together with the gas fired boilers, 25.5 MW thermal power. (Photo: provided by the press service of the MKS Group)

Reduced Production Costs and a Short Payback Period

The opening ceremony of the power plant took place on November 14th, 2019. During the ceremony the power plant was set into operation from the control center. “The cheap electrical output and thermal power produced by the MWM TCG 2032B V16 engine allows us to significantly reduce the production costs”, says Roman Panteleev, Chief power engineer of NLMK Ural. “The work was well-organized and coordinated, the generating equipment was constructed in a short time”. According to calculations, the payback period of the energy center will be three years.

You can find more information and insights in this video of the opening ceremony of NLKM-Ural in Nizhniye Sergi on YouTube.

Higher Flexibility, Reliability and Environmental Friendliness of Power Plant due to MWM TCG 2032B V16 Unit

The MWM gas engines of the TCG 2032 series are perfectly geared to the challenges of a dynamic market environment. The models in the output range of 3,000 – 4,500 kWel meet the high requirements of a broad range of applications and guarantee efficiency, reliability, flexibility and environmental sustainability, together with low lifecycle costs and high profitability. The TCG 2032B V16 gas engine with a fast ramp-up option allows to switch between normal and fast start requirements for each start request. This feature is becoming increasingly important due to growing renewable capacity.

Glance into the brand new energy center of the steel production company NLMK Ural with the MWM TCG 2032 gas engine. (Photo: provided by the press service of the MKS Group)

Further Information:

- MKS Group of Companies

- YouTube Video: NLMK Ural Opening Ceremony

- MWM YouTube Channel mwmgenset

- MWM Gas Engine TCG 2032B V16

- MWM Press Release: Location-Independent, Flexible Power and Heat Generation: Modular Power Plant Supplies Energy in Russia

- MWM Gas Applications: CHP for Industrial or Commercial Facilities

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com