Energy Security in the Manufacturing and Utilities Industries through Cogeneration and Trigeneration Plants

Mannheim, August 21, 2019

The sharp rise in summer temperatures pose a challenge with regard to the energy supply in the manufacturing and utilities industries. Trigeneration is an eco-friendly, cost-saving solution concept for industrial cooling processes without any interruptions. Besides trigeneration, combined heat and power generation is especially useful for the energy-intensive industry as well as medium-sized enterprises.

CHP as Sustainable, Efficient Solution in Greenhouse Horticulture

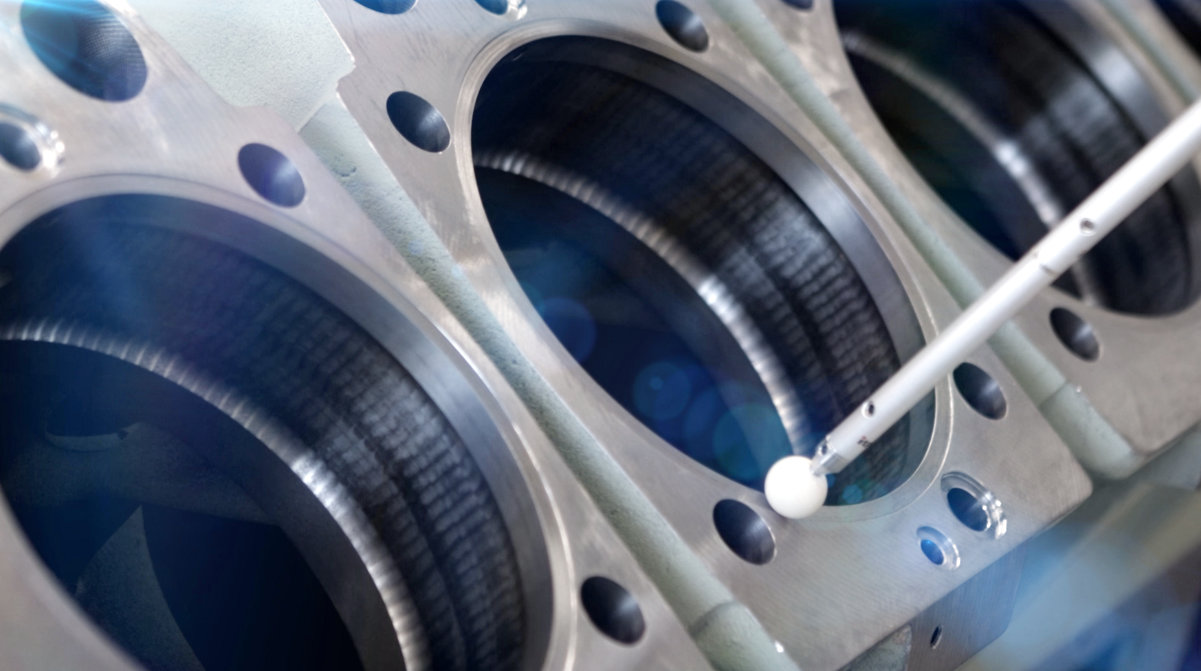

Currently, cogeneration is one of the best solutions for greenhouse horticulture without using fossil fuels. Due to the much better utilization of the primary energy, gas engine-driven cogeneration power plants are among the most efficient, eco-friendly methods for the operation of greenhouses. In addition to the actual cogeneration, the CO2 from the gas engine’s exhaust gas can be used as fertilizer in greenhouses. A special exhaust treatment unit purifies the exhaust gas in such a way that usable carbon dioxide enters the greenhouses.

Until industrial alternatives that do not depend on fossil fuels are developed for air-conditioning and illuminating greenhouses, cogeneration remains one of the most sustainable and profitable solutions on the market, especially when fueled with biogas.

The air-conditioning of office or residential buildings during heat waves becomes much more efficient and inexpensive if small, inefficient A/C units are replaced with custom-tuned cogeneration power plants for the operation of dedicated cooling systems.

Turning Heat into Cold: Trigeneration for Cooling Processes in the Food Industry

Trigeneration plants can increasingly be found in larger buildings that need a considerable amount of air-conditioning or process cooling in addition to their heating needs in winter. This includes hotels, hospitals, office buildings, and highly energy-intensive food manufacturing plants and other industrial cooling processes.

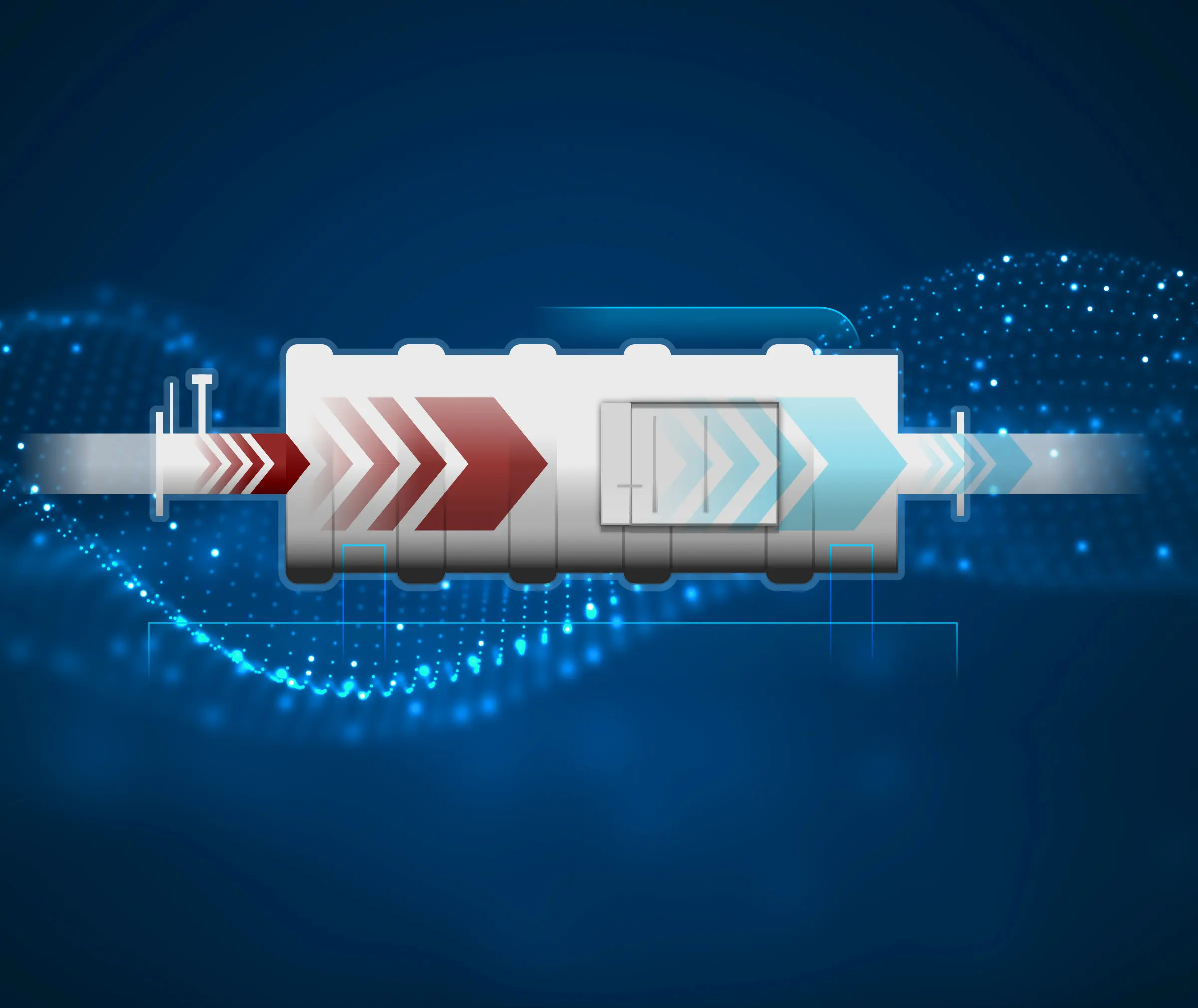

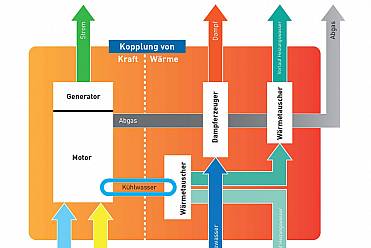

In addition to heat and power, the combination of a cogeneration power plant with an absorption refrigerator for trigeneration can also provide cooling. In the absorption refrigerator, the exhaust heat from the power generation in the cogeneration power plant runs a thermal compressor, which in turn drives a cooling cycle. Depending on the substrate mix used, the thermal efficiency is 60 to 80 percent. Trigeneration makes sure that the primary energy is utilized efficiently even in the warmer summer months. Especially food production plants can use trigeneration for their industrial cooling processes, such as the production and storage of food.

Apart from delivering CHP plants and power gensets with an excellent efficiency at attractive prices, Caterpillar Energy Solutions also provides competent advice and services for the development of integrated cogeneration power plants and power plant concepts in order to make good use of the entire value chain of distributed energy generation under specific conditions. MWM gas engines produced by Caterpillar Energy Solutions can be customized for maximum output despite high ambient temperatures and high setup altitudes.

Further information:

- MWM Cogeneration Power Plants

- MWM Gas Engines and Power Gensets

- Cogeneration & Trigeneration

- MWM press release: CHP Plant with MWM TCG 2016 V16 Gas Engine in Chocolate Factory Honored as Highly Sustainable Energy Concept

- MWM press release: Cogeneration as Key Technology for Eco-Friendly, Efficient Greenhouse Horticulture

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com