Cogeneration Plant with MWM Engine in Frankfurt Nordwest Hospital Designated CHP Plant of the Month

Mannheim, March 15, 2016

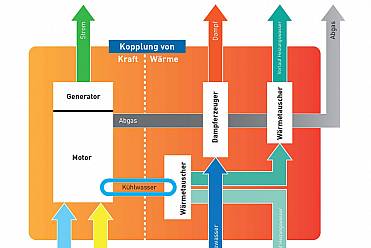

In February 2016, “Energie & Management” magazine designated the combined heat and power plant that had been installed in the Frankfurt Nordwest hospital in May 2015 as the CHP plant of the month. The CHP plant manufacturer SES had rolled out the cogeneration project together with Mainova Energiedienste GmbH. The CHP plant, which runs with an MWM TCG 2016 V16C gas engine, especially stands out due its optimum customization to the circumstances of the hospital. Moreover, it has increased the economic efficiency and security of supply of the Nordwest hospital and improved its primary energy factor.

Special Circumstances Require Special Measures: Containers in Two Sizes and Noise Insulation Panels

Originally, the Nordwest hospital had been supplied by two gas-powered Omnical boilers with a thermal output of 2.3 MWth and a Buderus gas boiler with an output of 740 kWth. Instead of replacing the entire old system, Mainova Energiedienste GmbH – the company responsible for planning and rolling out the cogeneration project – integrated the new CHP plant in the hospital’s existing infrastructure.

Apart from the integration in the existing facilities, the cramped confines at the plant location – the parking lot in front of the hospital’s administrative building – represented a major challenge in connection with the installation of the CHP plant. This problem was solved by setting up two containers of different sizes. Moreover, the hospital’s requirement that the noise emission of the CHP plant must not exceed 40 dB(A) was fulfilled by means of a massive 30-cm high-density concrete building envelope and an additional noise-absorbing layer lining the interior of the containers.

MWM Gas Genset: Efficient and Eco-Friendly

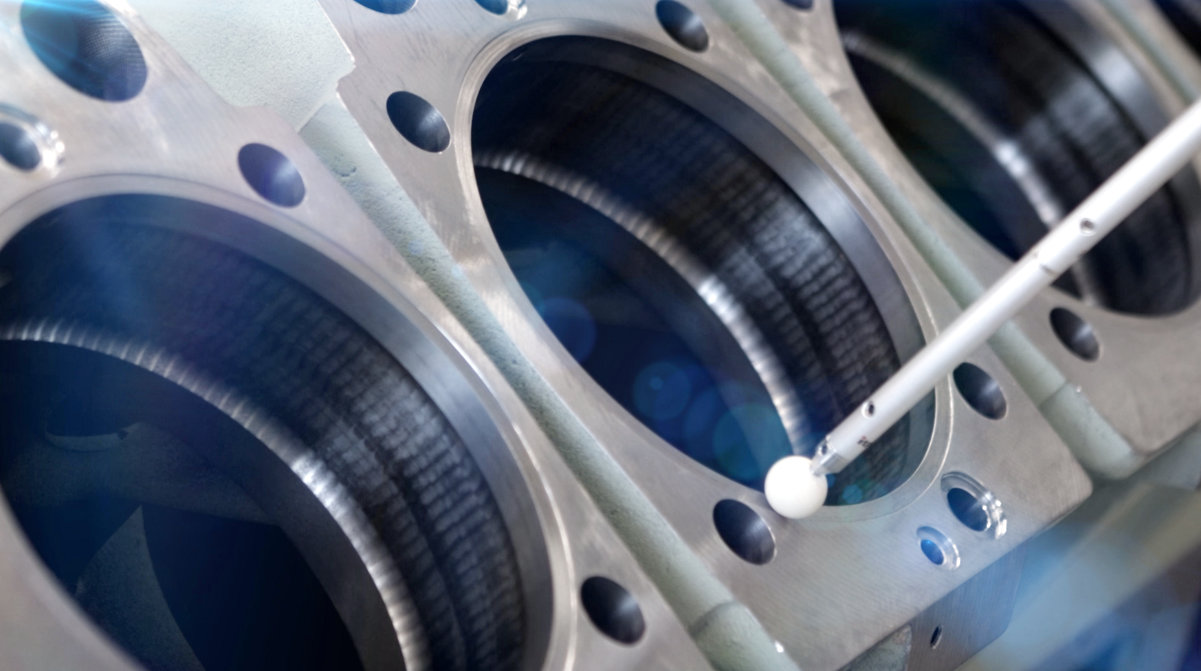

The core of the CHP plant – the MWM TCG 2016 V16C gas engine – runs on natural gas and delivers an electrical output of 800 kWel and a thermal output of 861 kWth. Apart from the gas genset, the scope of delivery of MWM comprised the plant control, the inflow and outflow ducts, the sound absorbers, the mixture cooler, the lubricant system, and the heat exchangers.

The cogeneration plant runs continually in winter and for only half of the time in buffer mode in summer. For this purpose, the existing 10-m3 hot-water tank was supplemented with a second buffer. Due to the high utilization in winter and the buffer operation in summer, the CHP plant achieves an overall efficiency of 87.8 percent, based on a total of 7,000 full-load hours/year. What is more, the operation of the CHP plant alone cuts the carbon emissions of the Nordwest hospital by one quarter a year. In this way, the hospital has improved its primary energy factor and fulfills the requirements of the Energy Saving Ordinance (EnEV).

Back in January 2016, we had already reported on the CHP plant in the Nordwest hospital in Frankfurt, Germany. The press release with further information on the MWM gas engine and the project in general is available here.

Further Information

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com