24/7 Energy Security through Modular Power Plant with MWM TCG 2020 V20 Gas Engine in Russia’s Largest Natural Stone Production and Processing Facilities

Mannheim, July 22, 2020

The Russian MWM distributor MKS Group of Companies has successfully commissioned the new energy center for the Russian industrial enterprise in Kartalinsky district of Chelyabinsk region. The new power plant will supply Russia’s largest natural stone production and processing company with power and heat. An MWM TCG 2020 V20 gas engine with an output of 2,000 kWel and an electrical efficiency of 44 percent constitutes the core of the new energy center.

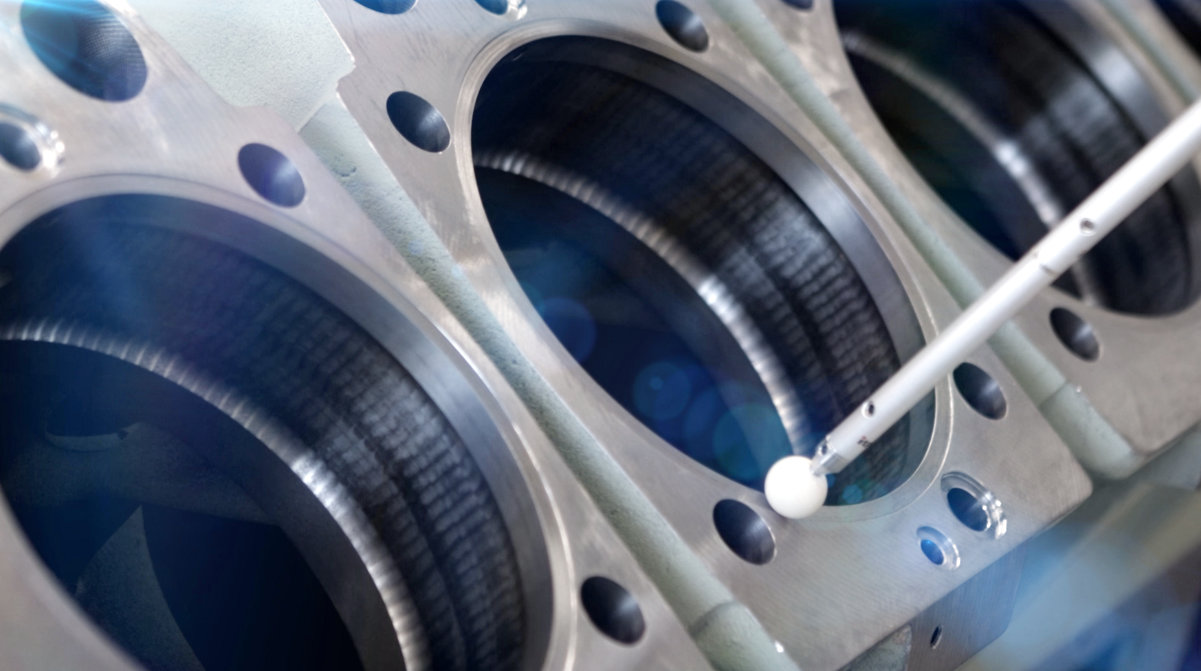

The MWM TCG 2020 V20 gas engines ensures uninterrupted power supply for sensitive natural stone production and processing workflows. (Photograph: MKS Group of Companies)

Stabilized Power Supply for a Stable Production Flow

The new highly efficient energy center stabilizes the company’s power supply and thus the entire production and manufacturing process. In 2019, the company opened a workshop with innovative equipment, which depends on uninterrupted power supply in 24-hour shift operation. The plant’s main products are high-quality mineral marble fillers with a high white proportion from the Eleninsky and Polotsky deposits. Microframe fillers and marble chips are used for the production of dry construction mixtures, paint coatings, linoleum, leather substitute materials, cleaning agents, ceramic tiles, tableware, paper, and even food and pharmaceutical products (e.g. for dental whiteners).

The plant, which mainly processes marble from the Eleninsky and Polotsky deposits, runs 24 hours a day and depends on uninterrupted power supply. (Photograph: MKS Group of Companies)

To maximize the energy security for the sensitive production and processing of natural stone, MKS has established a modular power plant (MPP) close to the factory. Thanks to their design, modular power plants can be set up anywhere in no time and can be used for distributed energy supply even in regions devoid of an infrastructure.

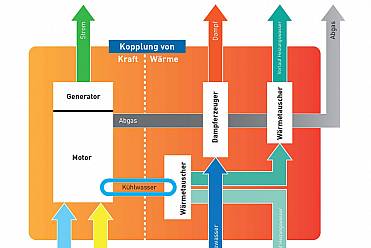

Combined Heat and Power (CHP) Decreases Energy Costs

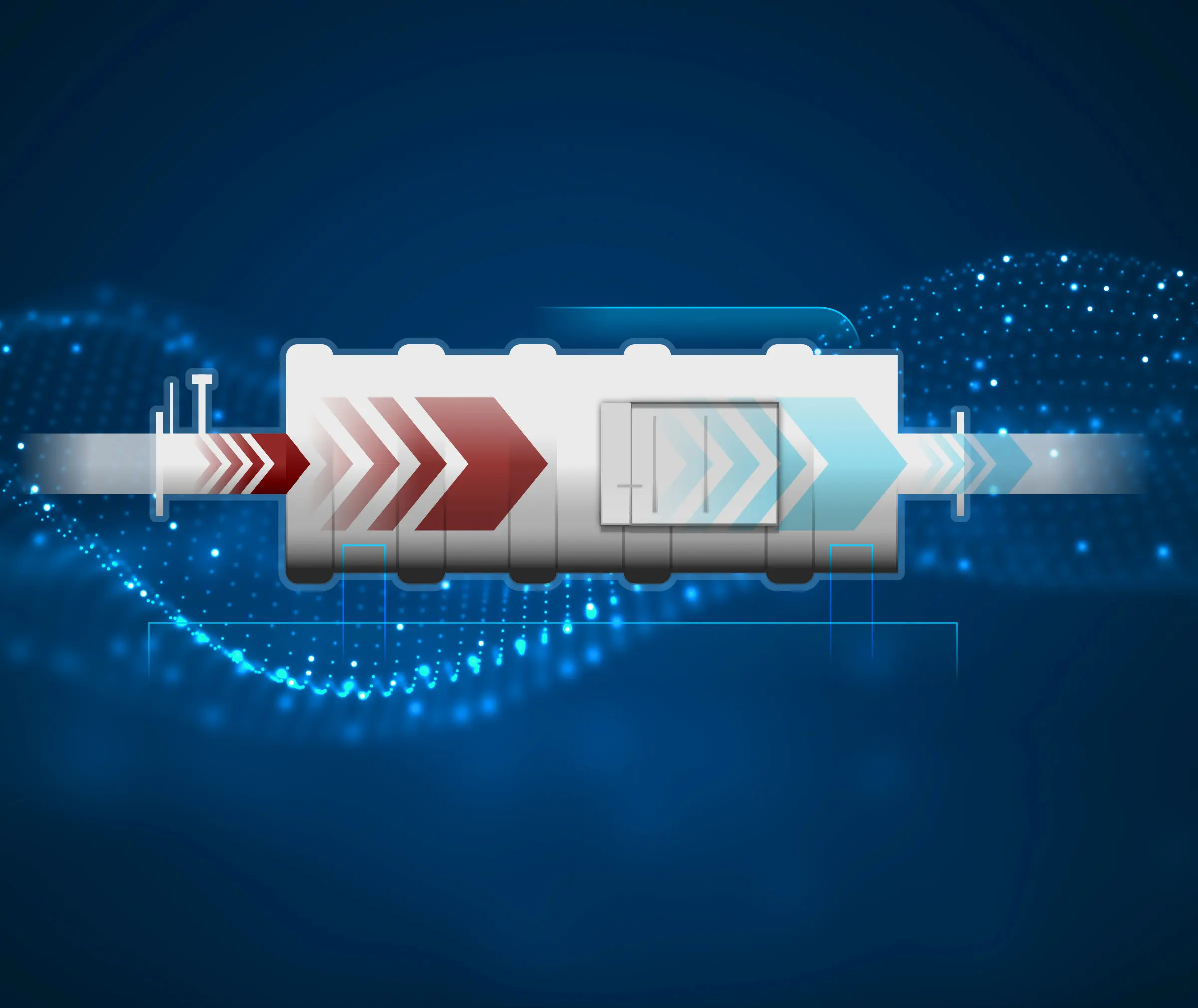

An MWM TCG 2020 gas engine forms the core of the power plant. The energy center employs combined heat and power (CHP) generation and produces power and heat energy directly where it is needed. Optionally, excess heat can be fed into a local or district heating network or be used for generating steam. Following the go-live of the power plant, this efficient form of energy generation reduced the company’s power costs to a third of the former expenses. Thus, the power plant’s payback period is only about three years.

MWM TCG 2020 for Optimum Electrical and Thermal Efficiency

The MWM TCG 2020 range of gas engines delivers outstanding efficiency, reliability, flexibility and environmental compatibility. The highly cost-efficient engines operate in an output range of 1,000 to 2,000 kWel and can be used with various gas types. The TCG 2020 is mainly used for CHP plants and for biogas applications worldwide.

Further information:

- MKS Group of Companies

- MWM TCG 2020 Gas Engine

- MWM Cogeneration Power Plants

- MWM reference sheet CHP power plant on premises of Sredneuralsky Copper Smelter in Russia

Contact Media

Aljoscha Kertesz

Manager Communications

T +49 621 48 18 35 76

E mwm-press@cat.com

Frank Fuhrmann

Online Editor

Member of DPV / German Press Association

T +49 621 48 18 35 16

E mwm-press@cat.com