TCG 2020

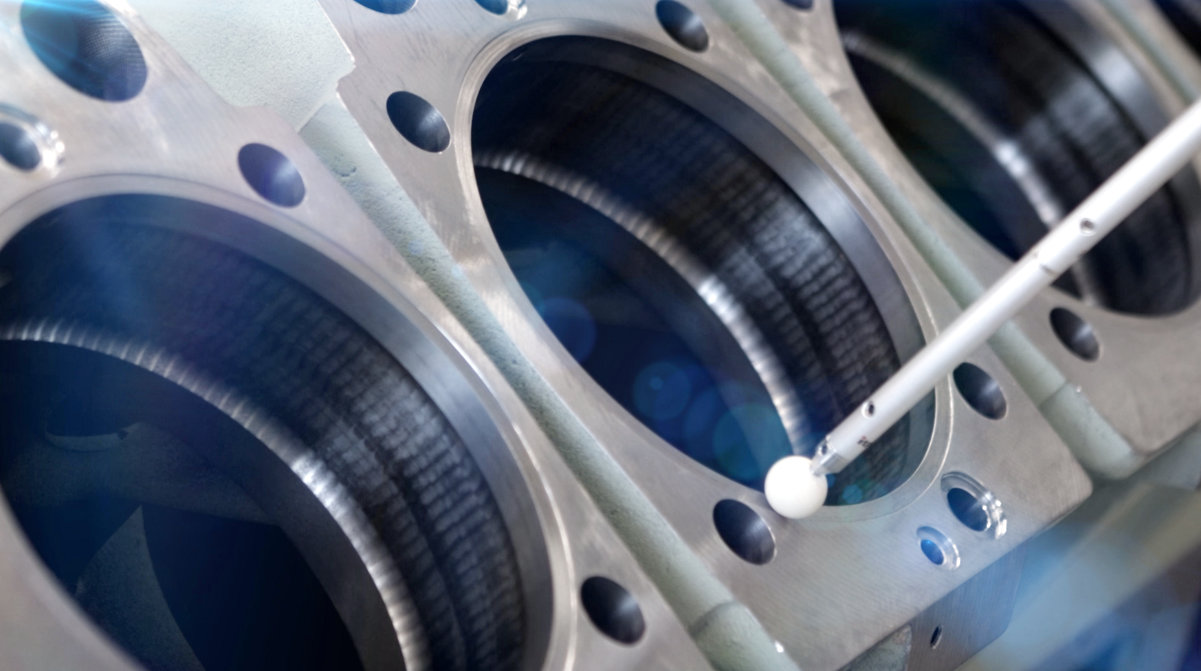

Gas Engine TCG 2020

1,000 - 1,560 kWel

Best electrical and thermal efficiency in its class. All gas types: natural gas, biogas, mine gas, landfill gas, sewage gas.

- Output range from 1,000 to 1,560 kWel

- Best electrical and thermal efficiency in its output class

- Runs on all gas types

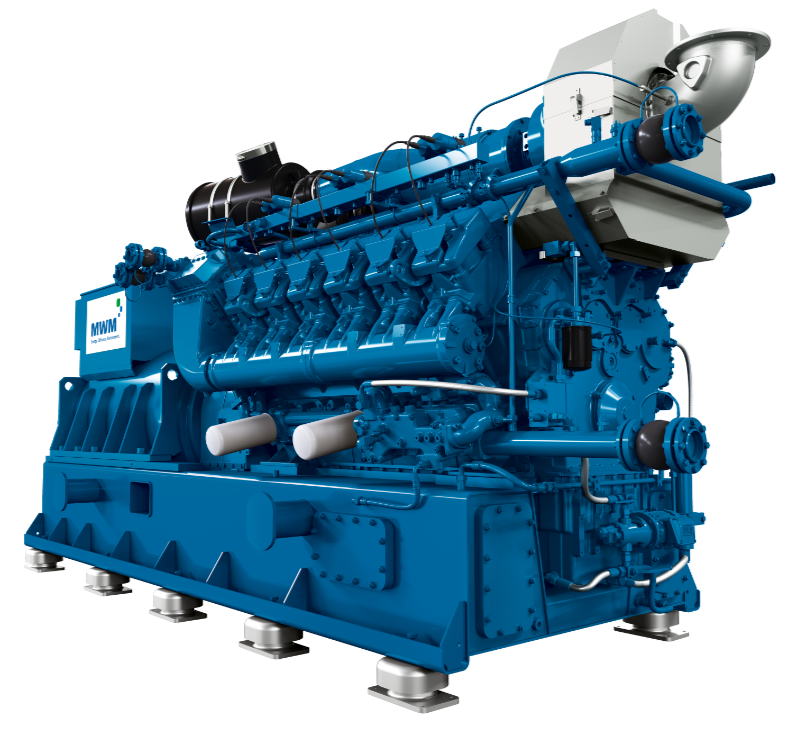

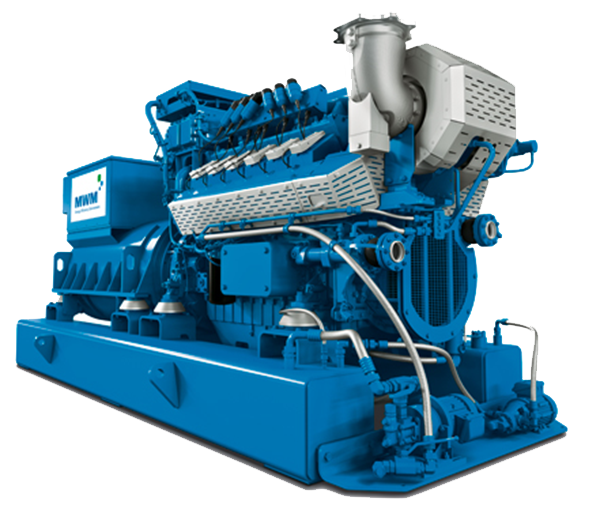

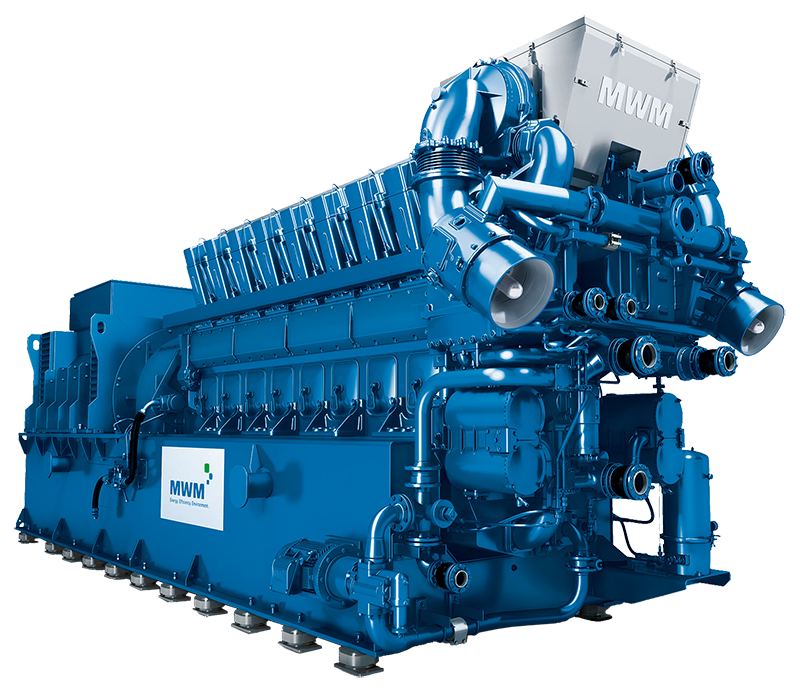

MWM Gas Engine TCG 2020 V12, V16 / TCG 2020 K

For the Highest Ratings in Ecology and Economy!

- Output range from 1,000 to 1,560 kWel

- Best electrical and thermal efficiency in its output class

- Runs on all gas types: natural gas, biogas, landfill gas, sewage gas, mine gas, etc.

- Low operating costs

- TCG 2020 is mainly used for CHP plants in Europe and for biogas worldwide

- The TCG 2020 V12 in the configuration RW (natural gas) and XW (biogas) is specifically optimized for the 1 MWel capacity range, with even lower operating and maintenance costs

- TCG 2020 K was especially adapted to non-ISO conditions such as high altitudes or high intake air temperatures in the field of natural gas

- More than 2000 power generators with approximately 2,800,000 kWel already installed around the globe

On this page

Description – MWM Gas Engine TCG 2020 / TCG 2020 K

High Reliability – MWM Gas Engine TCG 2020 / TCG 2020 K

Performance Data – MWM Gas Engine TCG 2020 / TCG 2020 K

Specifications and Service Intervals – MWM Gas Engine TCG 2020 / TCG 2020 K

Brochure – MWM Gas Engine TCG 2020

The MWM gas engines of the TCG 2020 series are perfectly geared to the challenges of a dynamic market environment. Our models in the output range of 1,000 – 1,560 kWel meet the high requirements of a broad range of applications and guarantee efficiency, reliability, flexibility and environmental sustainability, together with low lifecycle costs and high profitability.

Description – MWM Gas Engine TCG 2020 /

TCG 2020 K

TCG 2020 – High Profitability Thanks to High Efficiency

- Improvements of the intake duct and spark plug provide higher efficiency compared to predecessor model

- Miller valve control times increase genset efficiency

TCG 2020 V12 in the Configuration RW (Natural Gas) and XW (Biogas) – Increased Efficiency and Extended Useful Life in the 1 MWel Capacity Range

- For all natural gas and biogas applications in countries with 50 Hz networks

- Longer maintenance intervals for all natural gas applications extend useful life by two years

- Optimized electrical efficiency of 43 percent (under ISO conditions) for natural gas applications

- Optimized lubricant management

- Lower internal consumption through higher mixture cooler temperatures for natural gas applications

TCG 2020 K – Optimized for Isolated Operation and Non-ISO Conditions

- Load response in only seven steps

- Fast and reliable supply in the event of grid failures or in isolated operation

- Special 1,000 kWel variant available for high altitude setup and different intake air temperatures

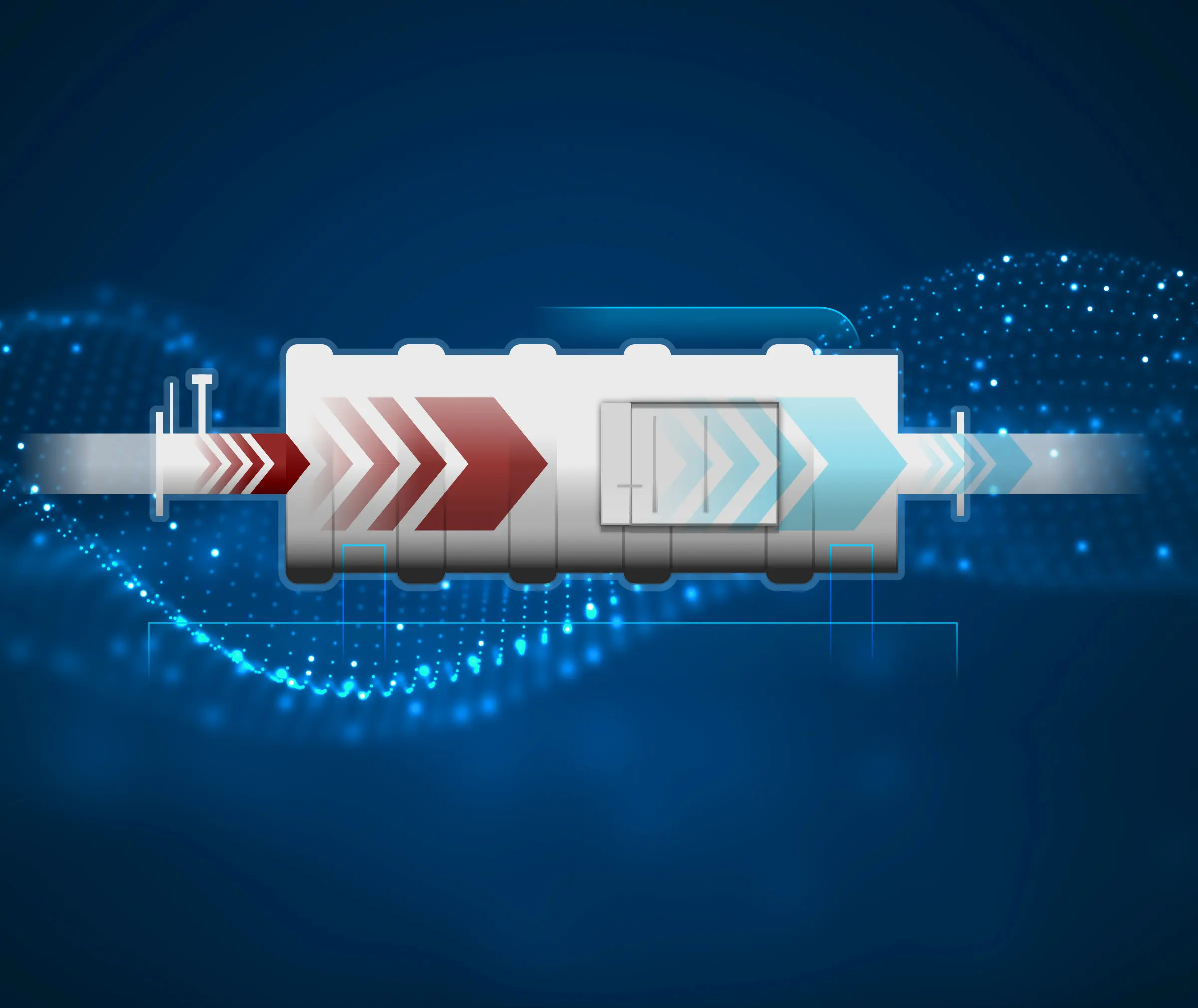

Higher Efficiency and Lower Pollutant Emissions

- Smaller dead spaces in combustion chamber ensure more complete combustion

- Reduced fuel consumption and CO and HC emissions

- This enables gas savings of up to 15 percent a year and increases the profitability of the plant

Higher Efficiency and Long Maintenance Intervals

- Effective crankcase ventilation increases efficiency by utilizing the returned combustible blow-by gas

- Optimized blow-by return and improved separation of the gas phase and liquid phase enable longer maintenance intervals for the turbocharger thanks to the clean intake air

K Editions: Maximum Output at Low Costs

- Improved output capacity of TCG 2020 K under non-ISO conditions and excellent load response through optimum turbocharger design with broad performance map

- New turbocharger TCR 16 for TCG 2020 with water-cooled bearing housing eliminates need for separate maintenance stages for the turbocharger

High Reliability – MWM Gas Engine TCG 2020 /

TCG 2020 K

Few Interruptions Due to Long Maintenance Intervals

- No more than two interruptions a year due to scheduled maintenance

- Longest interval until major overhaul compared to competitors

- Use of Xchange components enables time savings of up to 75 percent during the major overhaul, resulting in reduced costs

High Reliability through Mature Drive Technology in 60 Hz Range

- Engine can be operated with an optimum speed of 1500 RPM.

- Lower speed ensures stable and complete combustion, resulting in lower CO emissions and less component wear and tear

Performance Data – MWM Gas Engine TCG 2020 /

TCG 2020 K

Natural gas applications, NOx ≤ 500 mg/Nm3 *

| TCG 2020 V12 RW = Optimized for high total efficiency at requested power | ||

|---|---|---|

| Engine type | 50 Hz | |

| Electrical output | kW | 1000 |

| Thermal output ± 8% | kW | 1056 |

| Electrical efficiency | % | 43.0 |

| Thermal efficiency | % | 45.4 |

| Total efficiency | % | 88.4 |

| Power to heat ratio ** | 0.95 | |

| TCG 2020 V12 K K = Optimized for robustness and low CAPEX | TCG 2020 V12 R = Optimized for high total efficiency | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 1125 | 1125 | 1200 | 1200 |

| Thermal output ± 8% | kW | 1251 | 1262 | 1189 | 1196 |

| Electrical efficiency | % | 41.0 | 40.7 | 43.7 | 43.4 |

| Thermal efficiency | % | 45.6 | 45.6 | 43.3 | 43.2 |

| Total efficiency | % | 86.6 | 86.3 | 87.0 | 86.6 |

| Power to heat ratio ** | 0.90 | 0.89 | 1.00 | 1.00 | |

| TCG 2020 V16 K K = Optimized for robustness and low CAPEX | TCG 2020 V16 R = Optimized for high total efficiency | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 1500 | 1500 | 1560 | 1560 |

| Thermal output ± 8% | kW | 1675 | 1686 | 1576 | 1589 |

| Electrical efficiency | % | 40.9 | 40.6 | 43.3 | 43.0 |

| Thermal efficiency | % | 45.7 | 45.7 | 43.8 | 43.8 |

| Total efficiency | % | 86.6 | 86.3 | 87.1 | 86.8 |

| Power to heat ratio ** | 0.89 | 0.89 | 0.99 | 0.98 | |

* With 5% O2 and dry exhaust gas

** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Biogas, Landfill Gas, and Sewage Gas Applications, NOx ≤ 500 mg/Nm3 *

| TCG 2020 V12 XW = Optimized for operation with biogases at requested power | TCG 2020 V12 X = Optimized for operation with biogases | |||

|---|---|---|---|---|

| Engine type | 50 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 1000 | 1200 | 1200 |

| Thermal output ± 8% | kW | 1035 | 1192 | 1201 |

| Electrical efficiency | % | 42.6 | 43.0 | 42.7 |

| Thermal efficiency | % | 44.1 | 42.7 | 42.7 |

| Total efficiency | % | 86.7 | 85.7 | 85.4 |

| Power to heat ratio ** | 0.97 | 1.00 | 1.00 | |

| TCG 2020 V16 X = Optimized for operation with biogases | |||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output | kW | 1560 | 1560 |

| Thermal output ± 8% | kW | 1566 | 1580 |

| Electrical efficiency | % | 42.7 | 42.3 |

| Thermal efficiency | % | 42.9 | 42.8 |

| Total efficiency | % | 85.6 | 85.1 |

| Power to heat ratio ** | 1.00 | 0.99 | |

* With 5% O2 and dry exhaust gas

** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Specifications and Service Intervals –

MWM Gas Engine TCG 2020 / TCG 2020 K

Dimensions and Weights

| TCG 2020 V12 RW = Optimized for high total efficiency at requested power XW = Optimized for operation with biogases at requested power | ||

|---|---|---|

| Engine type | 50 Hz | |

| Length | mm | 4660 |

| Width | mm | 1810 |

| Height | mm | 2210 |

| Dry weight genset | kg | 11200 |

| Bore / stroke | mm | 170/195 |

| Displacement | dm3 | 53.1 |

| Speed | min-1 | 1500 |

| Mean piston speed | m/s | 9.8 |

| TCG 2020 V12 K K = Optimized for robustness and low CAPEX | TCG 2020 V12 R = Optimized for high total efficiency X = Optimized for operation with biogases | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Length | mm | 4790 | 5970 | 4790 | 5970 |

| Width | mm | 1810 | 1790 | 1810 | 1790 |

| Height | mm | 2210 | 2210 | 2210 | 2210 |

| Dry weight genset | kg | 11700 | 13000 | 11700 | 13000 |

| Bore / stroke | mm | 170/195 | 170/195 | 170/195 | 170/195 |

| Displacement | dm3 | 53.1 | 53.1 | 53.1 | 53.1 |

| Speed | min-1 | 1500 | 1500 | 1500 | 1500 |

| Mean piston speed | m/s | 9.8 | 9.8 | 9.8 | 9.8 |

| TCG 2020 V16 K K = Optimized for robustness and low CAPEX | TCG 2020 V16 R = Optimized for high total efficiency X = Optimized for operation with biogases | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Length | mm | 5430 | 6640 | 5430 | 6640 |

| Width | mm | 1810 | 1790 | 1810 | 1790 |

| Height | mm | 2210 | 2210 | 2210 | 2210 |

| Dry weight genset | kg | 13300 | 14900 | 13300 | 14900 |

| Bore / stroke | mm | 170/195 | 170/195 | 170/195 | 170/195 |

| Displacement | dm3 | 70.8 | 70.8 | 70.8 | 70.8 |

| Speed | min-1 | 1500 | 1500 | 1500 | 1500 |

| Mean piston speed | m/s | 9.8 | 9.8 | 9.8 | 9.8 |

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Service Intervals

| TCG 2020 V12, V16, V12 K, V16 | First service (check valve clearance) | Cylinder head inspection | Major overhaul |

|---|---|---|---|

| Natural gas, purified biogas, sewage gas, and landfill gas | 4000 oh | 32000 oh* | 64000 oh |

| Unpurified biogas, sewage gas, and landfill gas | 2000 oh | 16000 oh* | 64000 oh |

| TCG 2020 V12 RW = Optimized for high total efficiency at requested power XW = Optimized for operation with biogases at requested power | First service (check valve clearance) | Cylinder head inspection | Major overhaul |

|---|---|---|---|

| Natural gas | 4000 oh | 40000 oh* | 80000 oh |

| Purified biogas, sewage gas, and landfill gas | 4000 oh | 32000 oh* | 64000 oh |

| Unpurified biogas, sewage gas, and landfill gas | 2000 oh | 16000 oh* | 64000 oh |

* “at the latest”

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

MWM Spare parts

With its logistics center in Lorsch, Germany, MWM guarantees efficient and reliable global spare-part supply.

MWM Remote Asset Monitoring

Everything under control: More transparency and value for CHP plants with MWM Remote Asset Monitoring (RAM).

Gas Engines & Products

Distributed Power Plants

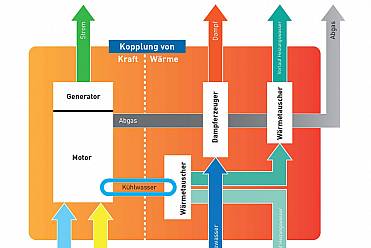

MWM stands for highly-efficient and eco-friendly combined heat and power (CHP) plants for distributed power generation.

Gas Engine TCG 3016

New development – greatly reduced operating and installation costs and fully digitized power plant control.

TCG 2032

High reliability. Low operating costs. Gas types: natural gas, landfill gas, sewage gas, mine gas, coke oven gas. Mainly used in large IPP projects with up to 100 MWel.

Container Cogeneration Plant

Compact modules for the TCG 3016, TCG 3020 and TCG 2020 gas engines. Complete turnkey systems for special applications.