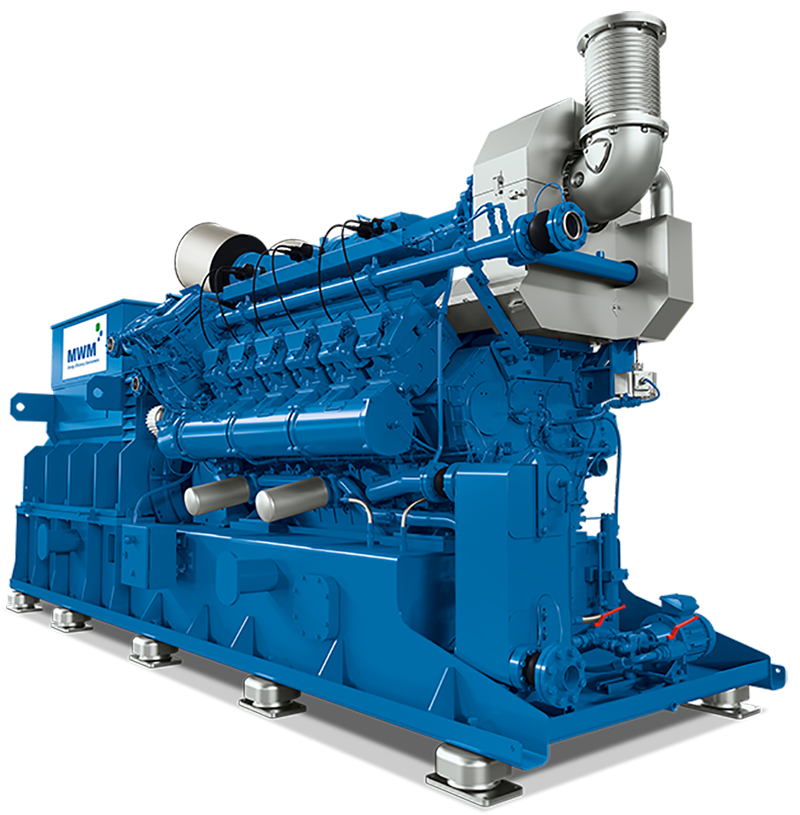

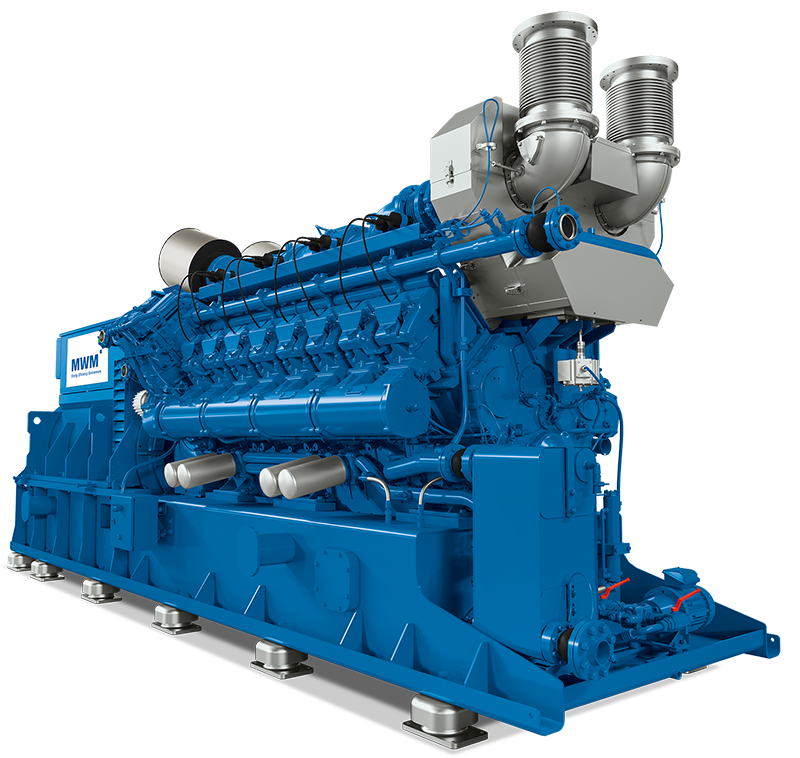

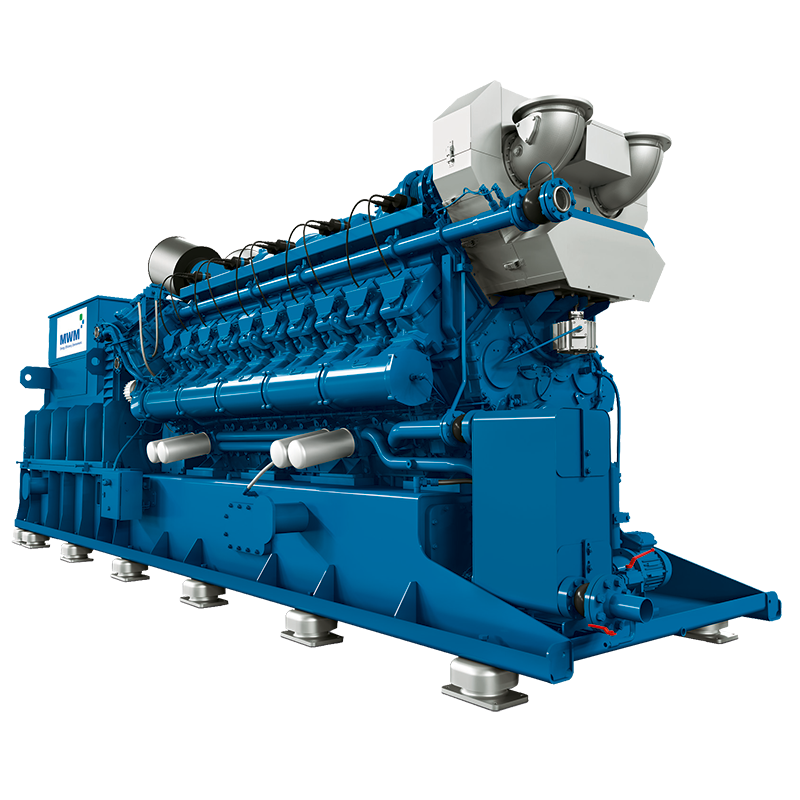

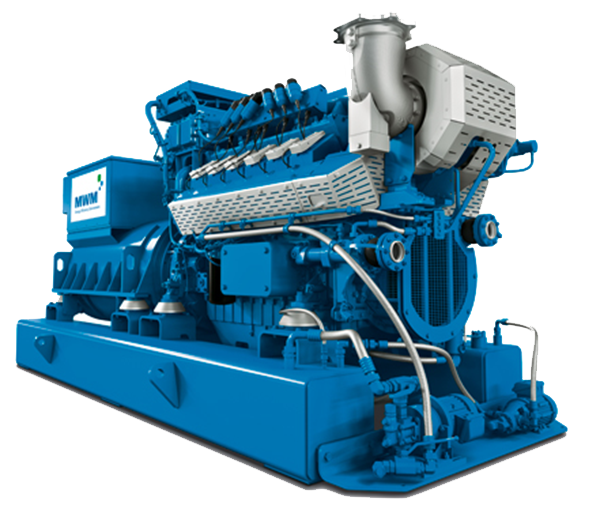

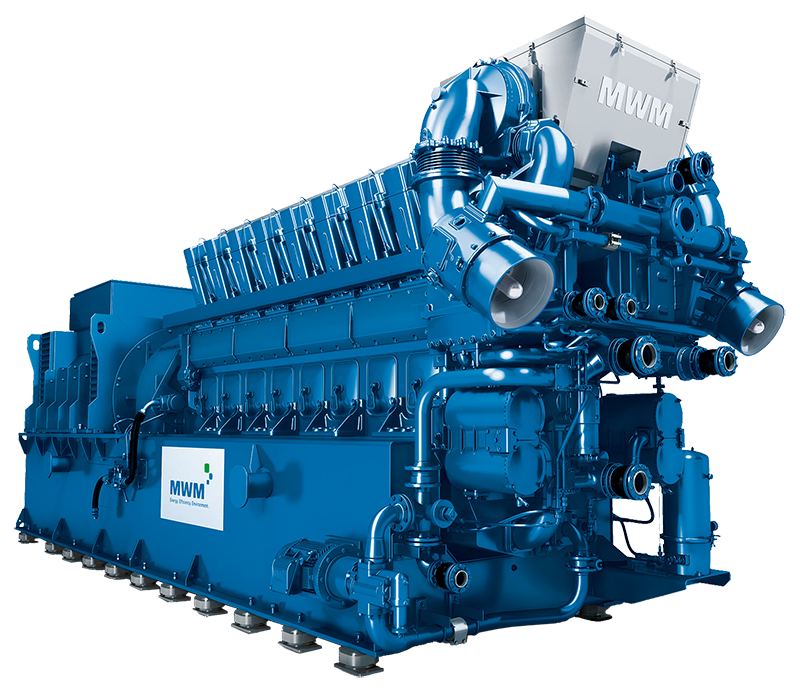

TCG 3020

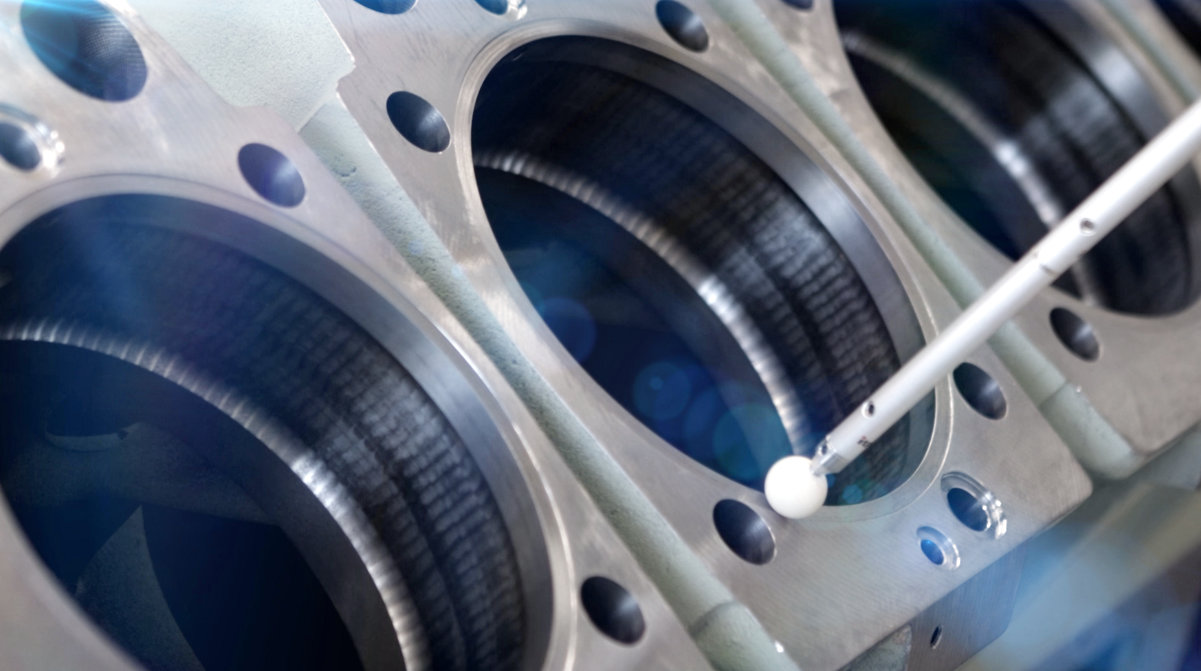

Gas Engine TCG 3020

1,380 - 2,300 kWel

The all-round talent. Smart, secure plant control. Higher output and profitability despite compact design.

- Output: 1,380 – 2,300 kWel

- Electrical efficiency of up to 45 percent (natural gas) and 43.6 percent (biogas)

- Very low oil consumption, high efficiency

- Low maintenance costs due to long service intervals

- Designed for natural gas operation with hydrogen admixture of up to 25 vol%

- Available as 50 Hz variant (V12, V16, V20) and as 60 Hz variant (V20)

MWM TCG 3020 Gas Engine: The All-Round Talent.

Flexible Use. Flexible Operation.

- Output: 1,380 – 2,300 kWel

- Flexible use for various applications and gas types, such as natural gas, biogas, APG, propane gas, hydrogen admixtures, and other gases

- MWM 25H2-Kit available for conversion for operation with hydrogen admixture of up to 25 vol%

- Electrical efficiency of up to 45 percent (natural gas) and 43.6 percent (biogas)

- High reliability and efficiency

- Low maintenance costs thanks to long service intervals of up to 80,000 hours until general overhaul

- Series with low operating costs

- Very low oil consumption, high efficiency

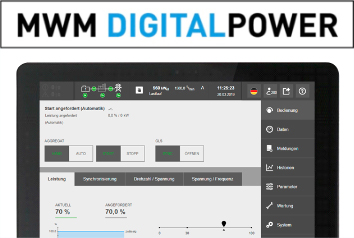

- High economic efficiency and availability thanks to digital control system TPEM (Total Plant & Energy Management)

- In the Z configuration, the TCG 3020 V20 is optimized for operation with propane, enabling the engine to deliver the best possible performance.

- The TCG 3020 V20 is available as 50 Hz variant or as 60 Hz variant (also for Z configuration).

On this page

Product video: MWM TCG 3020 – The all-round talent

Description – MWM Gas Engine TCG 3020

Performance Data – MWM Gas Engine TCG 3020

Specifications and Service Intervals – MWM Gas Engine TCG 3020

Brochure – MWM Gas Engine TCG 3020

Product Video: MWM TCG 3020 – The All-Round Talent

ЗАЯВЛЕНИЕ О КОНФИДЕНЦИАЛЬНОСТИ: при воспроизведении данного видео действует политика конфиденциальности YouTube. /// PRIVACY NOTE: If you play a video, privacy regulations of YouTube apply.

The MWM TCG 3020 gas engine effectively balances efficiency and reliability. The genset delivers up to 18 percent more output than its predecessor, though its dimensions are almost the same. Additionally, the new model features long service intervals with up to 80,000 operating hours until the next general overhaul (if the gas quality is high) and a total efficiency of more than 87 percent (with natural gas). Apart from the 50 Hz variant, the TCG 3020 V20 gas engine is also offered as 60 Hz variant.

Owing to their high reliability and profitability, the new gas engines with an output of 1,380 to 2,300 kWel are ready for the challenges of Industry 4.0. Thanks to the use of the digital power plant control TPEM (Total Plant & Energy Management), the gas engines are able to reach their full performance for maximum plant availability, capacity, and usability.

MWM retrofit kits for hydrogen operation

The gas engines of the TCG 3020 series can be used for operation with a hydrogen admixture of up to 25 vol%. With the MWM 25H2-Kit, operators of existing plants can retrofit their gas engines for operation with a hydrogen admixture of up to 25 vol%.

Description – MWM Gas Engine TCG 3020

Higher Efficiency and Performance

- Compared to the predecessor model, the TCG 3020 features the same size, a compact design and up to 18 percent more output.

- State-of-the-art technologies enable an output of 1,380 to 2,300 kWel and application-optimized engine types

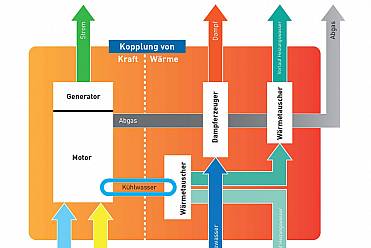

- High electrical efficiency of up to 45 percent (natural gas)/43.6 percent (biogas) and total efficiency of more than 87 percent (natural gas)/86 percent (biogas)

- Flexible use for various applications and gas types, such as natural gas, biogas, APG, propane gas, hydrogen admixtures, and other gases

Engine including TPEM plant control

- MWM hardware and software from the same manufacturer for comprehensive plant control

- Data analysis and optimum plant control combined in a single system

- Integrated secure remote maintenance solutions that are always available

- Full plant performance with maximum availability and reliability

Improved economic efficiency

- Long service intervals with up to 80,000 operating hours until the next general overhaul (if the gas quality is high)

- Low installation and operating costs thanks to high performance and low oil consumption of only 0.15 g/kWhel

TCG 3020 V20 in Z Configuration: High-Performance Propane Operation

The tried and tested TCG 3020 series has been supplemented with a new variant. In the Z configuration, the MWM TCG 3020 V20 gas engine runs on propane; in this way, the engine delivers a high performance density even at high altitudes. To ensure high quality and availability of the plant, the TCG 3020 V20 Z has undergone an extensive text cycle. The genset is available for parallel operation with the most important grid codes and for island-mode operation with improved load response. Moreover, the engine allows for alternate operation with natural gas.

Performance Data – MWM Gas Engine TCG 3020

Natural Gas Applications, NOx ≤ 500 mg/Nm3 *

| TCG 3020 V12 P = Optimized for high electrical efficiency | TCG 3020 V12 R = Optimized for high total efficiency | ||

|---|---|---|---|

| Engine type | 50 Hz | 50 Hz | |

| Electrical output | kW | 1,380 | 1,380 |

| Electrical efficiency ** | % | 45.0 | 44.0 |

| Thermal efficiency ** | % | 42.3 | 43.6 |

| Overall efficiency | % | 87.3 | 87.6 |

| Power to heat ratio *** | 1.06 | 1.01 | |

| TCG 3020 V16 P = Optimized for high electrical efficiency | TCG 3020 V16 R = Optimized for high total efficiency | ||

|---|---|---|---|

| Engine type | 50 Hz | 50 Hz | |

| Electrical output | kW | 1,840 | 1,840 |

| Electrical efficiency ** | % | 44.7 | 44.0 |

| Thermal efficiency ** | % | 42.6 | 43.6 |

| Overall efficiency | % | 87.3 | 87.6 |

| Power to heat ratio *** | 1.05 | 1.01 | |

| TCG 3020 V20 P = Optimized for high electrical efficiency | TCG 3020 V20 R = Optimized for high total efficiency | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 2,300 | 2,300 | 2,300 | 2,300 |

| Electrical efficiency ** | % | 45.0 | 44.4 | 44.0 | 43.7 |

| Thermal efficiency ** | % | 42.3 | 42.5 | 43.6 | 43.6 |

| Overall efficiency | % | 87.3 | 86.9 | 87.6 | 87.3 |

| Power to heat ratio *** | 1.06 | 1.04 | 1.01 | 1.01 | |

| TCG 3020 V20 PV = Optimized for high efficiency for requested power | TCG 3020 V20 RV = Optimized for high response for requested power | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 2,000 | 2,000 | 2,000 | 2,000 |

| Electrical efficiency ** | % | 44.4 | 43.9 | 43.7 | 43.4 |

| Thermal output | kW | 1,949 | 1,982 | 2,026 | 2,038 |

| Thermal efficiency ** | % | 43.3 | 43.5 | 44.2 | 44.2 |

| Overall efficiency | % | 87.7 | 87.4 | 87.9 | 87.6 |

| Power to heat ratio *** | 1.02 | 1.01 | 0.99 | 0.98 | |

* With 5% O2 and dry exhaust gas

** According to ISO 3046-1

*** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in these tables are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Natural Gas Applications, NOx ≤ 250 mg/Nm3 *

| TCG 3020 V12 P = Optimized for high electrical efficiency | TCG 3020 V12 R = Optimized for high total efficiency | ||

|---|---|---|---|

| Engine type | 50 Hz | 50 Hz | |

| Electrical output | kW | 1,380 | 1,380 |

| Electrical efficiency ** | % | 43.9 | 42.9 |

| Thermal efficiency ** | % | 43.2 | 44.5 |

| Overall efficiency | % | 87.1 | 87.4 |

| Power to heat ratio *** | 1.02 | 0.96 | |

| TCG 3020 V16 P = Optimized for high electrical efficiency | TCG 3020 V16 R = Optimized for high total efficiency | ||

|---|---|---|---|

| Engine type | 50 Hz | 50 Hz | |

| Electrical output | kW | 1,840 | 1,840 |

| Electrical efficiency ** | % | 43.6 | 42.9 |

| Thermal efficiency ** | % | 43.5 | 44.5 |

| Overall efficiency | % | 87.1 | 87.4 |

| Power to heat ratio *** | 1.00 | 0.96 | |

| TCG 3020 V20 P = Optimized for high electrical efficiency | TCG 3020 V20 R = Optimized for high total efficiency | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 2,300 | 2,300 | 2,300 | 2,300 |

| Electrical efficiency ** | % | 44.0 | 43.5 | 42.9 | 42.6 |

| Thermal efficiency ** | % | 43.1 | 43.3 | 44.6 | 44.6 |

| Overall efficiency | % | 87.1 | 86.8 | 87.5 | 87.2 |

| Power to heat ratio *** | 1.02 | 1.00 | 0.96 | 0.96 | |

| TCG 3020 V20 PV = Optimized for high efficiency for requested power | TCG 3020 V20 RV = Optimized for high response for requested power | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 2,000 | 2,000 | 2,000 | 2,000 |

| Electrical efficiency ** | % | 43.4 | 42.9 | 42.6 | 42.3 |

| Thermal output | kW | 2,031 | 2,065 | 2,123 | 2,136 |

| Thermal efficiency ** | % | 44.1 | 44.3 | 45.2 | 45.2 |

| Overall efficiency | % | 87.5 | 87.2 | 87.8 | 87.5 |

| Power to heat ratio *** | 0.98 | 0.97 | 0.94 | 0.94 | |

* With 5% O2 and dry exhaust gas

** According to ISO 3046-1

*** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in these tables are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Natural Gas Applications with 25 vol% Hydrogen (NOX ≤ 500 mg/Nm3* / 1.0 g/bhph*)

| Engine type Configuration | TCG 3020 V12 P+ High Efficiency plus 25H2-Kit = Optimized for high electrical efficiency with 25 vol.% hydrogen kit | TCG 3020 V12 R+ High Response plus 25H2-Kit = Optimized for high total efficiency with 25 vol.% hydrogen kit | |

|---|---|---|---|

| Electrical power** | kW | 1,380 | 1,380 |

| Electrical efficiency** | % | 44.6 | 43.9 |

| Thermal efficiency (±8 %) | % | 42.5 | 43.6 |

| Total efficiency | % | 87.1 | 87.5 |

| Power to heat ratio *** | 1.05 | 1.00 | |

| Engine type Configuration | TCG 3020 V16 P+ High Efficiency plus 25H2-Kit = Optimized for high electrical efficiency with 25 vol.% hydrogen kit | TCG 3020 V16 R+ High Response plus 25H2-Kit = Optimized for high total efficiency with 25 vol.% hydrogen kit | |

|---|---|---|---|

| Electrical power** | kW | 1,840 | 1,840 |

| Electrical efficiency** | % | 44.6 | 43.6 |

| Thermal efficiency (±8 %) | % | 42.6 | 43.9 |

| Total efficiency | % | 87.2 | 87.5 |

| Power to heat ratio *** | 1.05 | 0.99 | |

| Engine type Configuration | TCG 3020 V20 P+ High Efficiency plus 25H2-Kit = Optimized for high electrical efficiency with 25 vol.% hydrogen kit | TCG 3020 V20 R+ High Response plus 25H2-Kit = Optimized for high total efficiency with 25 vol.% hydrogen kit | |

|---|---|---|---|

| Electrical power** | kW | 2,300 | 2,300 |

| Electrical efficiency** | % | 44.6 | 43.6 |

| Thermal efficiency (±8 %) | % | 42.6 | 43.9 |

| Total efficiency | % | 87.2 | 87.5 |

| Power to heat ratio *** | 1.05 | 0.99 | |

| Engine type Configuration | TCG 3020 V20 PV+ High Efficiency for Requested Power plus 25H2-Kit = Optimized for high electrical efficiency at requested power with 25 vol.% hydrogen kit | TCG 3020 V20 RV+ High Response for Requested Power plus 25H2-Kit = Optimized for high total efficiency at requested power with 25 vol.% hydrogen kit | |

|---|---|---|---|

| Electrical power** | kW | 2,000 | 2,000 |

| Electrical efficiency** | % | 44.0 | 43.3 |

| Thermal efficiency (±8 %) | % | 43,6 | 44,6 |

| Total efficiency | % | 87.6 | 87.9 |

| Power to heat ratio *** | 1.01 | 0.97 | |

* for 5 % O2 and dry exhaust gas

** according to ISO 8528-1

*** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Propane gas applications, NOx ≤ 250 mg/Nm3 *

| TCG 3020 V20 Z = Optimized for operation with propane gas | |||

|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | |

| Electrical output | kW | 1,880 * | 1,880 * |

| Electrical efficiency ** | % | 41.8 | 41.5 |

| Thermal output | kW | 2,063 | 2,078 |

| Thermal efficiency ** | % | 45.9 | 45.8 |

| Overall efficiency | % | 87.7 | 87.3 |

| Power to heat ratio *** | 0.91 | 0.91 | |

* The electrical output of 1880 kWel is also achieved with natural gas applications.

** According to ISO 3046-1

*** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in these tables are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Biogas, Landfill Gas, and Sewage Gas Applications, NOx ≤ 500 mg/Nm3 *

| TCG 3020 V12 X = Optimized for operation with all biogases | TCG 3020 V16 X = Optimized for operation with all biogases | ||

|---|---|---|---|

| Engine type | 50 Hz | 50 Hz | |

| Electrical output | kW | 1,380 | 1,840 |

| Electrical efficiency ** | % | 43.6 | 43.6 |

| Thermal efficiency ** | % | 42.7 | 42.7 |

| Overall efficiency | % | 86.3 | 86.3 |

| Power to heat ratio *** | 1.02 | 1.02 | |

| TCG 3020 V20 X = Optimized for operation with all biogases | TCG 3020 V20 XV = Optimized for operation with all biogases for requested power | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 2,300 | 2,300 | 2,000 | 2,000 |

| Electrical efficiency ** | % | 43.6 | 43.4 | 43.2 | 42.9 |

| Thermal output | kW | 2,254 | 2,206 | 1,922 | 1,983 |

| Thermal efficiency ** | % | 42.8 | 40.5 | 41.5 | 41.5 |

| Overall efficiency | % | 86.4 | 83.9 | 84.7 | 84.4 |

| Power to heat ratio *** | 1.02 | 1.07 | 1.04 | 1.03 | |

* With 5% O2 and dry exhaust gas

** According to ISO 3046-1

*** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in these tables are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Biogas, Landfill Gas, and Sewage Gas Applications, NOx ≤ 250 mg/Nm3 *

| TCG 3020 V12 X = Optimized for operation with all biogases | TCG 3020 V16 X = Optimized for operation with all biogases | ||

|---|---|---|---|

| Engine type | 50 Hz | 50 Hz | |

| Electrical output | kW | 1,380 | 1,840 |

| Electrical efficiency ** | % | 42.6 | 42.6 |

| Thermal efficiency ** | % | 43.4 | 43.5 |

| Overall efficiency | % | 86.0 | 86.1 |

| Power to heat ratio *** | 0.98 | 0.98 | |

| TCG 3020 V20 X = Optimized for operation with all biogases | TCG 3020 V20 XV = Optimized for operation with all biogases for requested power | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Electrical output | kW | 2,300 | 2,300 | 2,000 | 2,000 |

| Electrical efficiency ** | % | 42.7 | 42.2 | 42.2 | 41.7 |

| Thermal output | kW | 2,346 | 2,293 | 1,999 | 2,060 |

| Thermal efficiency ** | % | 43.5 | 42.0 | 42.2 | 43.0 |

| Overall efficiency | % | 86.2 | 84.2 | 84.4 | 84.7 |

| Power to heat ratio *** | 0.98 | 1.00 | 1.00 | 0.97 | |

* With 5% O2 and dry exhaust gas

** According to ISO 3046-1

*** The power to heat ratio is calculated by dividing the electrical efficiency by the thermal efficiency. Please remember that this is a theoretical value that may deviate from actually measured values.

The values given in these tables are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Specifications and Service Intervals – MWM Gas Engine TCG 3020 V20

Dimensions and Weights

| Engine type | TCG 3020 V12 50Hz | TCG 3020 V16 50Hz | |

|---|---|---|---|

| Bore / stroke | mm | 170/195 | 170/195 |

| Displacement | dm3 | 89.0 | 89.0 |

| Speed | min-1 | 1500 | 1500 |

| Mean piston speed | m/s | 9.8 | 9.8 |

| Length | mm | 5080 | 6100 |

| Width | mm | 1815 | 1815 |

| Height | mm | 2190 | 2190 |

| Dry weight genset | kg | 12900 | 17400 |

| TCG 3020 V20 | TCG 3020 V20 Z = Optimized for operation with propane gas | ||||

|---|---|---|---|---|---|

| Engine type | 50 Hz | 60 Hz | 50 Hz | 60 Hz | |

| Bore / stroke | mm | 170/195 | 170/195 | 170/195 | 170/195 |

| Displacement | dm3 | 89.0 | 89.0 | 89.0 | 89.0 |

| Speed | min-1 | 1500 | 1500 | 1500 | 1500 |

| Mean piston speed | m/s | 9.8 | 9.8 | 9.8 | 9.8 |

| Length | mm | 6600 | 7738 | 6500 | 7738 |

| Width | mm | 1815 | 1815 | 1815 | 1815 |

| Height | mm | 2190 | 2551 | 2190 | 2551 |

| Dry weight genset | kg | 21400 | 21200 | 17980 | 21200 |

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Service Intervals

| First Service * | Cylinder head inspection | General overhaul | |

|---|---|---|---|

| High gas quality (natural gas, mine gas (purified) propane gas) | 4000 oh | 40000 oh ** | 80000 oh |

| Medium gas quality (biogas (purified), mine gas) | 4000 oh | 32000 oh ** | 64000 oh |

| Gas quality Low (biogas, landfill gas, sewage gas) | 3000 oh | 24000 oh ** | 48000 oh |

* “after commissioning (E10)”

** at the latest

The values given in this table are information purposes only and not binding. The information given in the offer is decisive. Other unit variants with other generators are available.

Brochure – MWM Gas Engine TCG 3020

Further information on the TCG 3020 gas engines is available here.

Brochure – MWM 25H2-Kit for TCG 3020

New plants with the TCG 3020 series are now suitable for natural gas operation with a hydrogen admixture of up to 25 vol%, both for 50 Hz and for 60 Hz. Retrofit solutions are available for existing plants.

TPEM Digital Plant Control

With its comprehensive digital power plant control TPEM (Total Plant & Energy Management), MWM revolutionizes the control standard for energy solutions.

MWM Remote Asset Monitoring

Everything under control: More transparency and value for CHP plants with MWM Remote Asset Monitoring (RAM).

Gas engines & Products

Gas Engine TCG 3016

New development – greatly reduced operating and installation costs and fully digitized power plant control.

TCG 2032

High reliability. Low operating costs. Gas types: natural gas, landfill gas, sewage gas, mine gas, coke oven gas. Mainly used in large IPP projects with up to 100 MWel.

Container Cogeneration Plant

Compact modules for the TCG 3016, TCG 3020 and TCG 2020 gas engines. Complete turnkey systems for special applications.